The industrial coating market is constantly searching for innovative solutions to meet the needs of high productivity and a reduction in process and management costs, with a special focus on environmental sustainability.

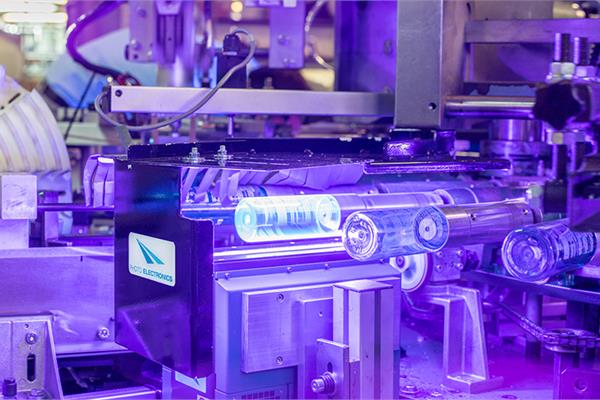

For this purpose, at its R&D laboratories in Berlingo, Arsonsisi has recently developed a new line of coatings for UV LED (Light Emitting Diodes) lamp curing.

Coatings for UV LED lamps are 100% dry residue, i.e. they do not contain volatile organic compounds, water or solvents, whereas crosslinking using UV LED lamp curing technology allows significant energy savings to be achieved.

A UV LED lamp can also be combined, on the coating line, with a traditional Hg UV lamp - with mercury vapours - using "dual cure" hybrid UV coatings.

Each UV LED lamp emits UV rays in the UV-A/UV-V area, using the emission of single LED diodes mounted in arrays.

UV LED lamps are monochromatic lamps (365nm, 385nm, 395nm and 405nm) with very low consumption, unlike traditional lamps, which emit a spectrum with different wavelengths.

UV LED technology offers many advantages over the use of traditional Hg UV lamps. For example, UV LED lamps:

- do not emit ozone

- are free from mercury and hazardous substances

- do not emit UV-B and UV-C rays

- have low heat emission

- are equipped with instant on/off switching

- have adjustable power from 0-100%

- have a partial irradiance width

- have very small dimensions that allow them to be easily inserted in production machinery

- guarantee the option of placing several lamps side by side, obtaining continuous irradiation

- crosslink coatings instantly

- last about 10 times longer.

UV LED lamps are used with excellent results for crosslinking inks, coatings and adhesives.

The new UV LED lamp coatings by Arsonsisi are ideal for coating metal and plastic materials. They are widely used mainly in cosmetic packaging, and in components produced in large batches, such as bottle caps.