The holistic approach of the market segment Industrial & Transportation Coatings of Evonik’s Coating Additives business line ensures increased lifecycles of coated objects, while saving resources.

Protecting customers’ high value assets with high performance solutions is one of our major drivers. Particularly when it comes to sustainability, complexity/cost reduction, durability, and visual appearance. We offer deep knowledge of additives and resins to formulate eco-friendly coatings, particularly for waterborne, high-solid, and powder formulations. Find out more on www.coatino.com!

On COATINO® Campus we additionally offer a variety of trainings, lab videos and live event recordings with a focus on new, innovative products.

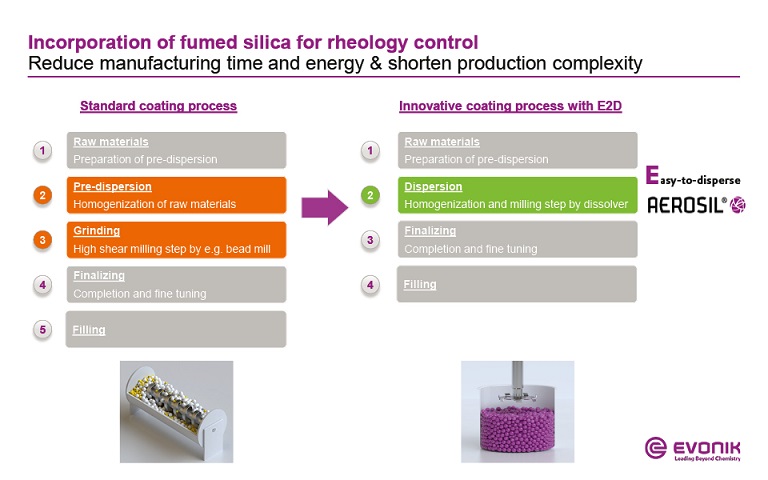

Innovative manufacturing process simplifies dispersion of AEROSIL® fumed silicas

The new product group ‘AEROSIL® Easy-to-disperse’ helps reducing equipment demand, processing time, and expense.

The dispersion process for rheological additives - such as fumed silica - used to be complex and time-consuming. Paint manufacturers had to grind the silicas in an intensive grinding step using a bead mill to ensure they were homogeneously dispersed in the formulation and could thus develop their full rheological potential.

When using the new AEROSIL® E products, the use of an energy-intensive bead mill is no longer necessary, as the new silicas can be dispersed in just a single grinding step using a dissolver. This saves time and money and proves to be a clear advantage especially in the production of clear coatings.

Achieving the next level of durability with TEGO® Cure 100

Energy and costs can be saved by coating heat-stable surfaces. The new hardener TEGO® Cure 100 ensures that the coating cures at room temperature, thus eliminating the need for costly and energy-intensive drying in the oven. At the same time, the surface is heat-stable up to 650°C during application.

TEGO® Cure 100 was specially developed for surfaces that are continuously exposed to high temperatures. It is suitable for silicone resins as well as silicone combination. The high solids content of more than 99% reduces solvent emissions to a minimum. It is free of organo-tin compounds and heavy metals and enables formulations of sustainable coatings with a low VOC content.

In combination with silicone resins, e.g. SILIKOPHEN® AC 900 for direct-to-metal coatings, it offers excellent corrosion protection for heavy duty applications and excellent weathering stability.

Next generation solutions

Formulating eco-friendly Industrial & Transportation Coatings for today, tomorrow and beyond. We focus on a broad portfolio of specialized coating effects to support the industry in its continuous move towards sustainable technologies and raw materials.