AkzoNobel and Microsoft will use quantum chemical computation to simulate chemical reactions.

AkzoNobel

and Microsoft have announced a partnership aimed at exploring how quantum computing could help accelerate the development of high-performance and more sustainable paints and coatings. Scientists from both companies will collaborate in a virtual laboratory using Microsoft Azure cloud services.

“This is a really exciting partnership which has the potential to be truly groundbreaking. We’re incredibly proud to partner with Microsoft and investigate how we can take our digital research into a new dimension. Innovation demands collaboration and this is a fantastic way for us to keep pushing boundaries so we can make a sustainable and long-lasting difference to our customers and the planet,” stated the Chief Technology Officer of AkzoNobel, Klaas Kruithof.

“The promise of quantum computing and other Azure services to accelerate solving chemistry and materials problems – and their associated workloads – is immense. We’re thrilled to partner with AkzoNobel to drive new value and deliver world-changing impact,” added Matthias Troyer, a scientist from Microsoft’s Azure Quantum programme.

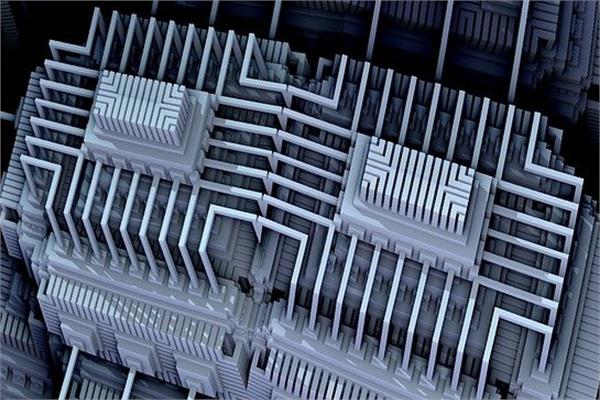

Quantum chemical computation is capable of simulating chemical reactions with a high level of accuracy, so it is expected to offer innovative possibilities for industrial applications, as it might help to overcome many of the practical boundaries associated with traditional laboratory methods, such as availability of raw materials, physical equipment capacity constraints, toxicity and environmental conditions.

“Combining our track record for pioneering product development with Microsoft’s cloud and quantum computing expertise represents another huge step forward in the digitization of our research. Up until now, the quality of traditional computer simulations hasn’t been up to the task. Microsoft’s Azure Quantum system offers incredible opportunities for us to take our research into an entirely new digital realm and speed up the development of new novel catalysts and chemical reactions,” declared Pim Koeckhoven, the technology director for R&D at AkzoNobel.