The Digital Factory Suite of Atotech leverages IIoT technologies and smart production data to optimise operations and increase performance.

Atotech has recently announced today that it has expanded its product offering with the Digital Factory Suite, a platform which combines a set of data-driven applications, systems integration capabilities and remote services. The new digital solution-based products will help customers transitioning to smart and more sustainable factory operations.

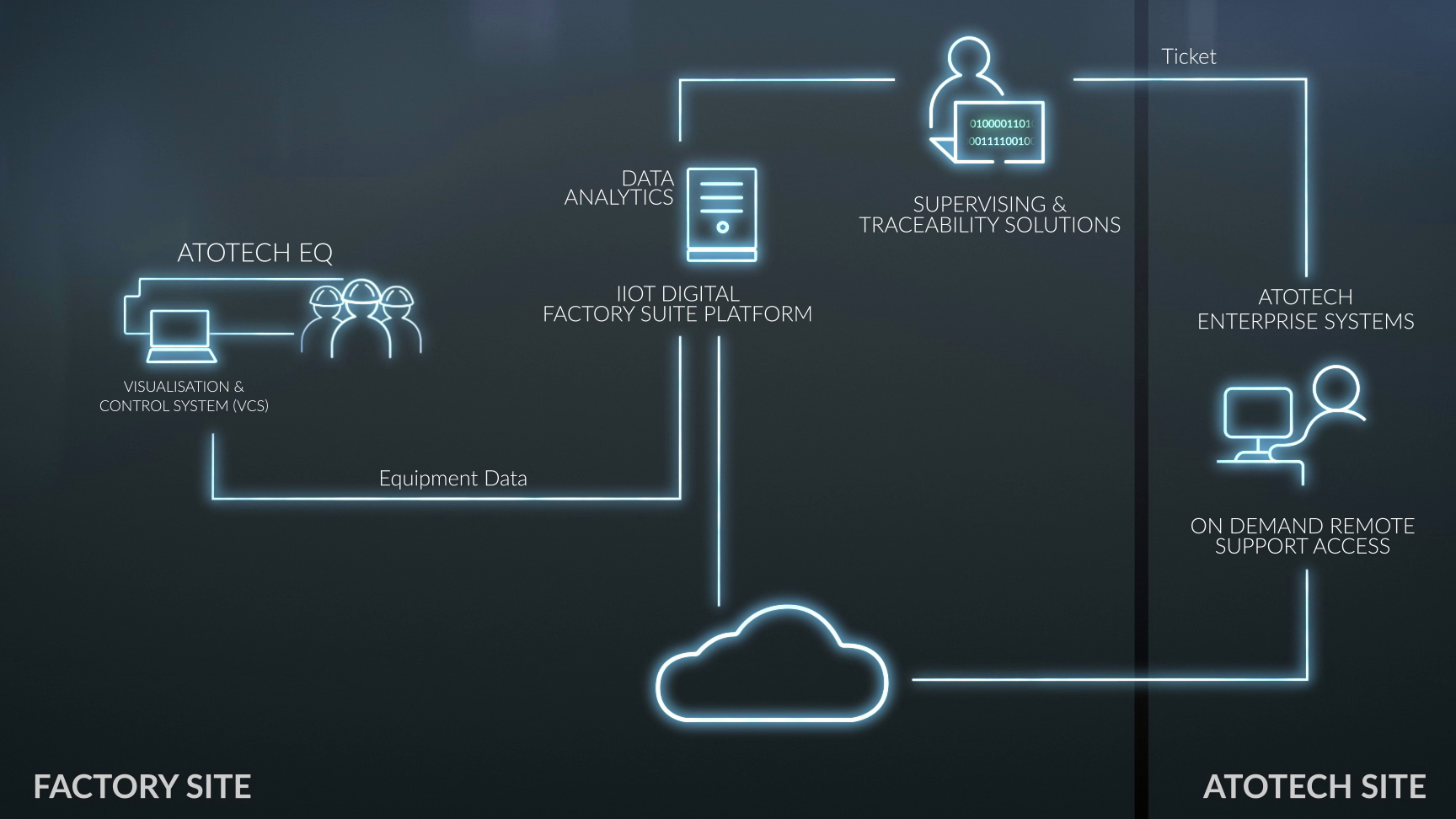

The Digital Factory Suite platform of Atotech connects to the on-site production equipment and continuously collects process and equipment data during manufacturing. Then, using advanced analytics

such as supervising and traceability, the collected data generate high-value insights into equipment and process conditions, enabling factory engineers to perform supervision, maintenance, quality inspections and other activities directly from their workplace. In addition, real-time condition monitoring and mobile alerts prevent defects and alarms from being overlooked, reducing the risk of unplanned downtime

“We are delighted that we can now offer our customers a solution which paves the way for them to transition from equipment automation and the Industrial Internet of Things to true smart-factory operations. We believe that with our Digital Factory Suite, our customers can generate unprecedented value. Even more so as it easily integrates with their existing production management system and allows for effective remote support,” has declared Harald Ahnert, the president of the Electronics division at Atotech.

The Digital Factory Suite is an add-on of the equipment-control software Visualization and Control System (VCS). Its functionalities significantly enhance the speed of secure customer support, especially when combined with the remote services offered by the company via an augmented-reality technology that is supported by a remote-access platform, ensuring a quick and sustainable assistance.

“Our digital suite of solutions in the field of software and service combines industrial software such as SCADA with the latest digital technology, such as IIoT, augmented reality, and digital twins. All features work together in optimizing operations, enabling faster support, and increasing production equipment performance in our customer’s factories. In doing so, we help our customers operate more efficiently, predict and schedule maintenance, eliminate unscheduled downtime, increase yield, and monitor and automate production to the highest possible degree,” has also added Stefan Stefanescu, the Head of Business Development Industrial Digital Solutions at Atotech.