BYK launched BYK-3568, a new silicone and polyether-modified acrylate specifically developed for automotive OEM coatings manufacturers.

BYK announced the launch of the silicone and polyether-modified acrylate BYK-3568, a new additive solution for formulators of automotive OEM clearcoats and topcoats.

BYK-3568 provides an answer to requirements for automotive OEM coatings, which need to be visually attractive, optimally protected and outstanding to the touch. Recently, there has been also a move towards individualization, such as with two-coloured applications, for example.

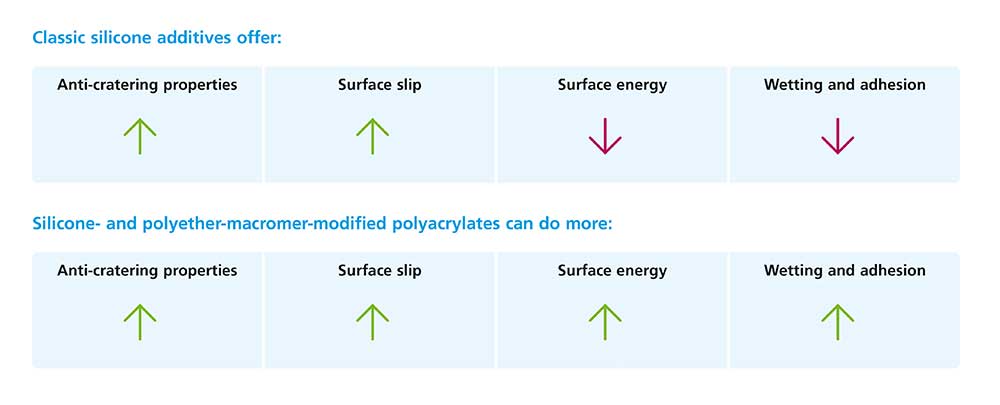

Moreover, the automotive industry is also looking to improve not only recoatability, but also the adhesion of stickers, printing inks or adhesives on the coating layer, especially where optimum surface slip is required.

BYK-3568’s advantages are particularly evident in clearcoats and topcoats, for which good recoatability or adhesion of the next coating layer is necessary. It also improves the substrate wetting as a moderately active silicone does, while at the same time increasing not only the coating’s surface energy but also its surface slip in a single step.