The new light-grey primer is enhanced with the water-based dispersion of graphene nanotubes from OCSiAl and provides stable surface resistivity.

Clear Skies Coatings, an American manufacturer and supplier of premium paints and coatings for the automotive industry, has launched an advanced conductive primer and adhesion promoter for the thermoplastic olefins (TPOs) substrate that do not produce VOCs emission, HAP or halogens

When powder coatings are applied on surfaces other than classical metal substrates, the low electrical resistivity of the TPOs used for automotive fascia, dashboards, cup holders, door coverings and roofing material must be modified with conductive adhesion promoters to improve the electrostatic efficiency. Carbon black or metal dust are commonly used to enable conductivity in primers. However, they negatively affect the basic properties of the coating and limit the range of available colours.

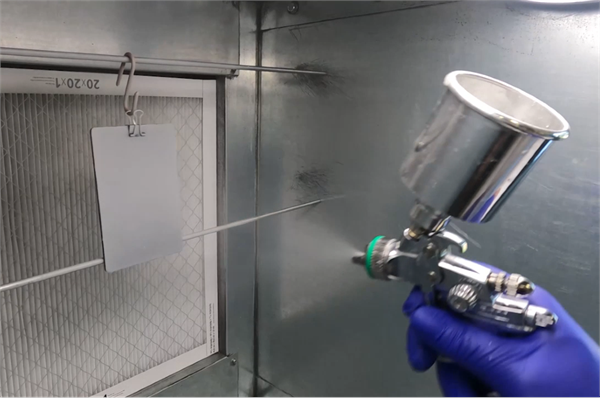

Clear Skies Coatings has then developed a colloidal suspension of powder in water enhanced with TUBALL™ COAT_E H2O 0.4%, a water-based dispersion of graphene nanotubes from OCSiAl. The new graphene nanotube solution can be sprayed with standard liquid equipment devices and provides several advantages for the automobile and wood industries that will benefit from increased cost efficiency, long-lasting performances and the ability to eliminate harmful emissions.

“Our Ad-Pro Zero patented formulation is made of a chemistry for powder coat. It is a conductive, sustainable, and durable gray-colored coating that combines the benefits of the traditional liquid adhesion promoters and conductive primer with the performance of powder coatings. It enables an easy and clean application on temperature-sensitive materials such as TPO and wood. The automotive sector is highly sensitive to this combination of benefits; our new solution is being assessed by TIER-1 in the US,” has stated David Detzler, the president of Clear Skies Coatings.

Containing less than 0.05 wt.% of graphene nanotubes, Ad-Pro Zero features a grey colour and can be coated with a thickness as low as 0.3 mil while achieving a surface resistivity <105 ohm/sq. The new product strongly improves the adhesion of the clearcoat, making it possible to reduce its thickness and enabling a wide spectrum of colour shades.

“This new coating with our graphene nanotubes is a revolutionary promoter for TPO-based car parts that has high performance, zero emissions of volatile organic compounds, zero hazardous air pollutants, and no halogens. For after-market facias, this powder slurry can be used as an ad-pro at about 6 to 8 microns,” has added Ian Fellows, the CEO of OCSiAl USA.