The UVC Solution developed by Fast and Fluid Management ensures that paint canisters remain free from mould and bacteria.

Fast and Fluid Management has recently presented its UVC Solution for paint preservation, a new technology specifically developed to prevent contamination and maintain the integrity of colorants over time by employing ultraviolet light to ensure that paint canisters remain free from mould and bacteria. By eliminating chemical biocides, it then reduces potential health risks while also contributing to a more sustainable operational environment.

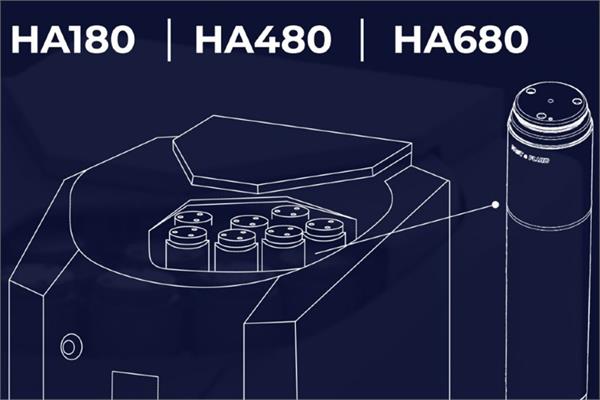

The lids of the canister are in fact equipped with UVC lights that emit precise wavelengths to disrupt the DNA of mould and bacteria, preventing their growth and ensuring the longevity and purity of colorants: the four strategically-placed LEDs per canister offer a multi-directional light exposure that minimises shadows and provides uniform disinfection across all surfaces.

The smart UVC Solution is fully programmable and autonomous, providing and effortless control and allowing users to adjust the intensity and duration through a simple interface, adapting to various operational requirements without needing manual intervention.

“In the innovative landscape of paint dispensing and preservation, Fast and Fluid Management continues to lead with cutting-edge solutions that enhance both the efficacy and environmental safety of colorant management. The introduction of our UVC Solution represents a significant advancement in our technology suite, aimed at meeting the modern challenges of paint preservation without reliance on biocides”, has stated the company.

Furthermore, the new technology has been designed to be retrofit-friendly, for facilities necessitating to upgrade their existing HA180 and HA480 equipment and enhance systems without extensive downtime or investments in new infrastructures.