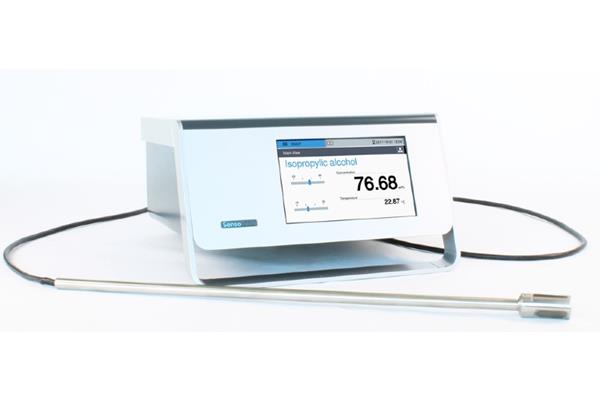

SensoTech GmbH has designed LiquiSonic® a high precision all-round analyzer for laboratories and technical centres.

To provide a functional solution to inline reaction monitoring, where little space is available, and under harsh conditions, SensoTech has developed a 3-in-1 sensor designed for reactors and small plants in laboratory and technology centres, which enables high precision monitoring of sonic velocity, attenuation and temperature.

LiquiSonic® is directly flanged into the reactor lid and provides an opportunity for complex polymerization or crystallization reactions monitoring, e.g. in down-scale reactors, and even in harsh conditions like high temperature or pressure.

"The selection of precise analyzer for laboratory vessels, small process reactors and technical centres presents the user with a major challenge. On the one hand the analyzer should be as space-saving as possible; on the other hand the device must withstand harsh and changing process conditions. Especially for R&D and process up-scaling tests specific parameters must be changed and inline monitored: high temperature levels, pressure drops, fluctuations in concentration level, process interruptions by impurities, secondary components etc. LiquiSonic® provides a solution to all these challanges", explains SensoTech.

Installation and features of LiquiSonic®

The sensor is fixed into the reactor lid and fits through every fitting >12mm. Process kinetics can be monitored inline and even under extreme process conditions in such pressurized miniplants or pilot reactors.

The LiquiSonic® system provides a space-saving design, separated sensor electronics and a user-friendly, multilingual controller with powerful data memory.

The LiquiSonic® Lab 3-in-1-sensor can be implemented for installations up to 160°C and 16bar and for measurements in highly viscous suspensions.

Special sensor materials like Hastelloy HC2000, tantalum or titanium protect against corrosion and promote long process life.

Applications and use of LiquiSonic®

The LiquiSonic

® Lab sensor is a 3-in-1 all-round analyzer, measuring sonic velocity, attenuation and temperature in real-time.

These parametres allow to monitor R&D processes or new designed active pharmaceutical ingredients as well, and LiquiSonic® can be applied also for the evaluation of nucleation and saturation curves of numerous mother liquors, the monitoring of the percentage of crystal content and the small-scale testing of polymerization processes. In this case, the changing sonic velocity and attenuation indicate the polymerization degree.

The results from such laboratory reactor or pilot plant studies are always available thanks to the internal long-time memory, and can be exploited for large-scale process optimization, where typically ultrasonic analyzers can be found as well.