The three new products from Evonik’s Business Line Coating Additives are characterized by excellent insulation properties & heat resistance, even at temperatures of up to 250 degrees Celsius. This provides the following performance and sustainability benefits for the use in the engineering, marine and construction sector.

Insulation coatings based on TEGO® Therm products substantially reduce energy loss and contribute to occupational health and safety as they can significantly reduce the temperature of hot surfaces. They also provide protection against moisture penetration and therefore prevent corrosion under insulation (CUI), which can significantly increase the service life of coated items.

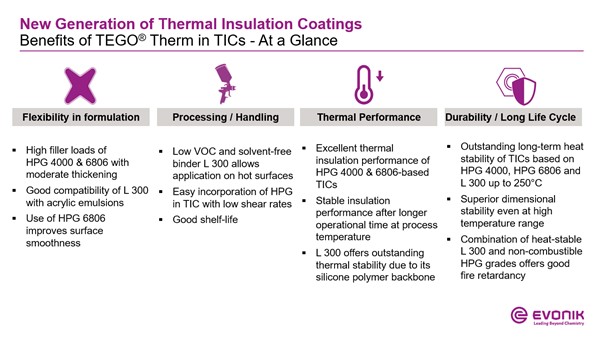

In contrast to conventional insulation systems, such as mineral wool, insulation coatings are easy to apply on complex 3D shapes via spray application, and can also be applied during ongoing operations, giving the benefit of dramatically reducing downtime and maintanance costs.

The new TEGO® Therm products in detail

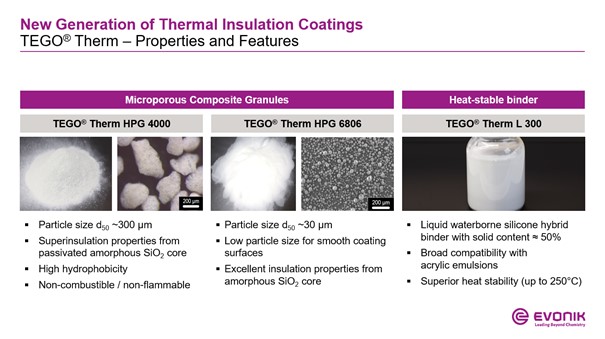

The two microporous composite granules TEGO® Therm HPG 4000 & TEGO® Therm 6806 are non-combustible, high-performance thermal insulation materials. They combine excellent insulation values with fire protection and sustainability. Both grades being pure minerals based on a proprietary fumed silicon dioxide composite which does not contain flame retardants based on halogens or heavy metals.

TEGO® Therm HPG 4000 granules are characterized by an average diameter of approx. 300 µm and contain a special IR passivation component for excellent insulation performance at the high temperature range.

TEGO® Therm HPG 6806 consists of finer particles of approx. 30 µm which allows formulation of coatings with smooth surfaces.

The product range is complemented by a water-based binder TEGO® Therm L 300 that can withstand temperatures of up to 250 degrees Celsius. Standard binders for TICs can only withstand temperatures no higher than 160 degrees. Given its excellent adhesion to various substrates, TEGO® Therm L 300 ensures excellent mechanical properties at high temperatures as well excellent compatibility to extend the temperature resistance of conventional acrylic based systems.

These products offer new solutions to long-standing issues in the areas of energy efficiency, safe touch and condensation control.

Personnel protection and safe touch:

When incorporated into a safe touch coating system, the thermal insulating TEGO® Therm granules help to prevent contact burns and provide the product flexibility needed to effectively cover potentially complex surfaces. The use of TEGO® Therm HPG 4000 & TEGO® Therm 6806 shows outstanding long-term performance in this application compared to other industry used particles, with the thermal protection being active and reliable for several years.

Corrosion under insulation:

When dealing with corrosion sensitive surfaces, most of the potential benefits can be achieved by using a heat stable ambient curing primer and a following insulative coating layer based on TEGO® Therm components. This combination shows excellent resistance to heat flow, combined with the perfect protection against Corrosion under insulation (CUI).

Condensation control:

When surface temperatures drop below the dew point, condensation forms and damage due to moisture is soon to follow. Coatings based on hydrophobic and thermal insulative TEGO® Therm components, have the potential to dramatically change the temperature profile of the substrate they are applied to, keeping coating surface temperature above the point where water will condense.

Learn more about TEGO® Therm and follow the link to the factsheet:

https://products.evonik.com/as...