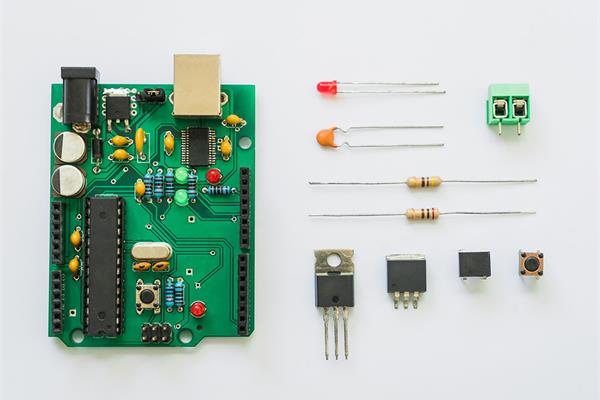

Cortec’s Eco Works® ESD proprietary technology is a range of formulations that encompasses environmentally safe and dissipating features, which is suitable for several industrial uses, especially for the protection of sensitive electronics.

Eco Works ESD is designed to replace traditional low density and high-density films. Despite it being comparable to HDPE, it contains no polyethylene but rather renewable raw materials ranging from 5 – 45%, depending on the formulation as well as anti-static properties, which reduce or eliminate static buildup.

Its formulations, which can be customized according to customers’ needs, are certified compostable per ASTM D6400 and EN 13432 and by Biodegradable Products Institute with BPI/USCC logo.

Eco Works ESD features

The exact time needed for Eco Works ESD products to biodegrade is dependent upon the conditions and activity of the disposal environment (temperature, soil quality, activity of microorganisms). When placed in a typical commercial composting environment, Eco Works ESD films will fully biodegrade into carbon dioxide and water within a matter of weeks, leaving no residue in finished compost. There is no eco-toxicity to the soil, plants or microorganisms involved in this process. Since microorganisms are the means for biodegradation, Eco Works ESD is shelf and curb stable and will retain its integrity until disposed of properly.

Eco Works ESD films can be curtailed to meet the requirements of the application ranging from flexible to rigid films.

It does not affect optical properties nor plastics used in the electronics industry and has no ill effects on solderability of PCB, meeting the requirements of IPC-J-STD-003C, Am1 (Edge Dip Solderability Tests).