The biobased organic admixture developed by Cortec has passed the testing for corrosion inhibiting admixtures.

Cortec® Corporation has recently announced that its MCI®-2005 is the first biobased, organic corrosion inhibiting concrete admixture to pass the ASTM G180 protocol

under ISO 17025 accredited testing.

The durability and the corrosion protection of metal products in concrete structures are two of the biggest issues concerning engineers and construction workers, as evidenced in recent tragedies such as the collapse of a residential building in Florida and the Morandi bridge in Italy. Cortec has therefore developed the MCI® Technology, a corrosion inhibiting admixtures that has proven efficiency even in severely corrosive environments.

Cortec Laboratories conducted the ASTM G180 test, one of the two corrosion performance tests specified in ASTM C1582 - Standard Specification for Admixtures to Inhibit Chloride-Induced Corrosion of Reinforcing Steel in Concrete. The lab provided the testing through its independent ISO 17025 accreditation.

The testing method, that measures corrosion inhibition ability in chloride environments, is used to ensure that admixtures meet the widely accepted industry standards for the selection and qualification of corrosion inhibiting admixtures. Manufacturers usually use it to screen new chemistry formulations for their potential as corrosion inhibiting admixtures.

Characteristics of MCI®-2005

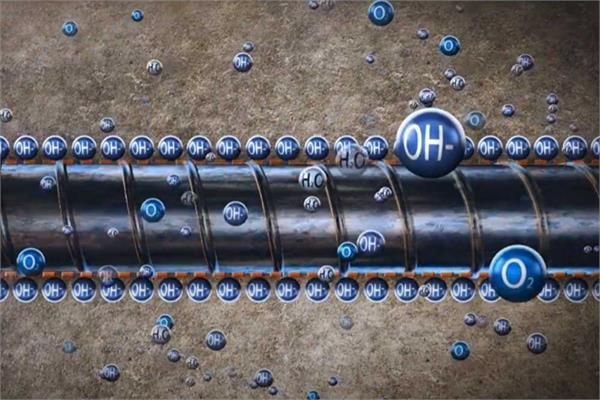

MCI-2005 is an organic, biobased corrosion inhibitor for protection of metallic reinforcement in concrete structures containing a blend of amine salts of carboxylic acids. Unlike calcium nitrite admixtures, which have a set accelerating effect that can cause early setup problems, MCI®2005 delays set time, making the concrete easier to work with and reducing the heat of hydration. In addition to this, it contains 67% USDA certified biobased content and is certified to meet ANSI/NSF Standard 61 for use in large potable water structures.

When incorporated into concrete, MCI®-2005 forms a protective molecular layer on embedded metals to inhibit corrosion. In new construction, this is quantified by an increase in critical chloride threshold and subsequent reduction in corrosion rates, once corrosion initiates. When used with repair mortars and grouts, it is also able to migrate into undisturbed concrete adjacent to the repair to protect reinforcement already in place.