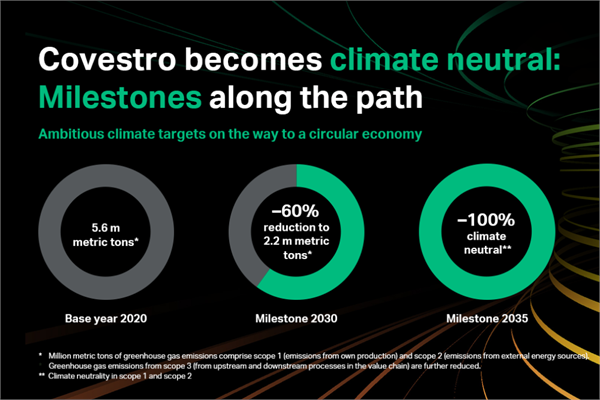

Covestro is committed to reducing greenhouse gas emissions by 2030 and net zero emissions by 2035 for scope 1 and scope 2.

Covestro announced its corporate commitment to achieve climate neutrality. In 2021, the company reduced its greenhouse gas emissions by 54% compared to 2005, surpassing the previous sustainability target set for 2025. Now, the company aims to become climate neutral and achieve net zero emissions by 2035 for scope 1 and scope 2. To achieve this goal, the company plans to cut GHG emissions from its production (scope 1) and from external energy sources (scope 2) from 60% to 2,2 million metric tons by 2030. Furthermore, indirect GHG emissions from upstream and downstream processes in the value chain (scope 3) will be further reduced. To achieve net zero emissions, Covestro plans investments from € 250 million to € 600 million by 2030.

To achieve the climate targets, Covestro will improve production processes and energy efficiency to achieve even more sustainable manufacturing. The use of catalyst technology will reduce nitrous oxide emissions. In addition, the company's plants around the world will gradually be converted to renewable electricity through the use of offshore and onshore wind energy and solar energy. Furthermore, the company intends to convert steam generation from fossil to renewable energy sources in the production process.

A portfolio of climatic neutral products

Covestro's corporate vision is to become fully circular and for that purpose, the company has planned to fully align its entire production and product range as well as all areas in the long-term to the circular concept. Among the climatic neutral products that have been added to the portfolio of Covestro products are:

- climate neutral MDI. Large quantities of MDI are used all over the world as a raw material for making rigid polyurethane (PU) foam, a very effective insulation material for buildings and refrigerators. 40 million metric tons of CO2 equivalent could be saved by using PU insulation. The new MDI types are climate neutral from the cradle to the gate thanks to the use of precursors from ISCC PLUS-certified mass-balanced organic waste and residual materials.

- climate neutral polycarbonate, made using raw materials from mass-balanced organic waste and residual materials as well as renewable energy. With the increasing trend of electromobility and the regulatory push for electric vehicles (EV), charging systems need to grow continuously, too. Using the climate neutral polycarbonate for EV charger could enable savings up to 450 kilotons CO2 equivalent by 2030.

“For the past two years, we have been working at full speed on our vision to become fully circular. We have already reached important milestones on this path and continue to set ourselves ambitious goals. Thanks to this approach, we are a pioneer in our industry and have accomplished many successes. One next milestone are our bold climate targets,” said Dr. Markus Steilemann, Chief Executive Officer of Covestro.

“In a circular economy, we can protect the climate, nature and resources and achieve sustainable growth that respects planetary boundaries. Covestro and the chemical industry are part of the solution. Sustainability cannot be done alone and will require a greater effort from everyone to achieve the goals of the Paris Climate Agreement. Policymakers, business and society must work together to achieve ambitious climate goals.”