Graphene-enhanced water-based coatings show improved corrosion resistance, aligning with Sparc's strategy to expand its eco-friendly additive portfolio and support ecosparc® trials.

Sparc has announced groundbreaking results from its initial tests on water-based acrylic epoxy coatings, demonstrating significant improvements in corrosion resistance through the incorporation of low-dosage, carefully selected graphene grades.

The tests, conducted using two industry-recognised electrochemical techniques, highlight graphene's transformative potential for water-based coatings compared to unmodified controls. Water-based coatings are increasingly preferred for their superior environmental benefits, using water as a carrier instead of fossil fuel-derived solvents. However, performance limitations have hindered their adoption in highly corrosive applications.

“There is an increasing push from the coatings industry towards more environmentally friendly water-based products, however their performance has not been adequate for wide scale industry adoption in corrosive applications. Our results clearly demonstrate a significant performance improvement with graphene which has the potential to unlock significant growth in this developing area of the coatings market. Pleasingly, these results have been achieved by leveraging Sparc’s proprietary knowledge and expertise working with graphene-based additives in the significantly larger solvent-based anticorrosion market and allows us to broaden our customer engagement,” has stated Nick O’Loughlin, Sparc’s Managing Director.

These findings align with Sparc’s strategy to expand into new markets while complementing its flagship ecosparc® product range. The testing was conducted using internally formulated water-based, two-pack acrylic epoxies applied to garnet-blasted cold-rolled steel. Graphene-enhanced coatings underwent rigorous testing with two advanced techniques:

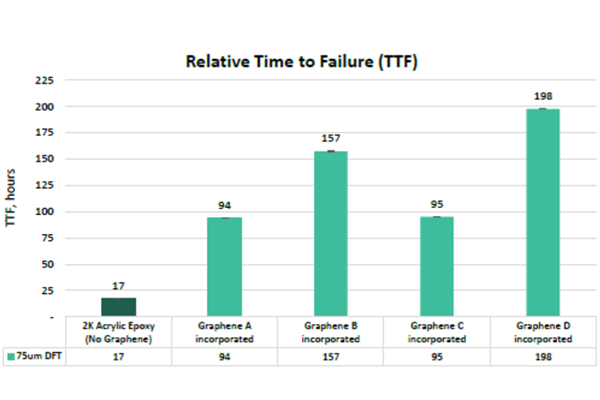

- Rapid Electrochemical Assessment of Paint (REAP): Demonstrated a 5.5x to 11.6x improvement in time-to-failure (TTF) compared to unmodified coatings.

- Accelerated Cyclic Electrochemical Technique (ACET): Showed significantly improved resilience, with less blistering and no corrosion after six cycles of cathodic polarisation.

The results were further validated using a commercially available water-based coating, showing similar levels of performance improvement with graphene incorporation. Water-based epoxy coatings are valued for their non-toxicity, low VOC emissions, and ease of application. Despite these benefits, their adoption has been limited due to inferior durability and performance compared to solvent-based alternatives. Tightening regulations on VOC emissions and increasing demand for sustainable solutions are driving innovation in this sector.

The global water-based epoxy market, valued at $1.6 billion in 2022, is projected to grow at a CAGR of 8.9%, reaching $2.9 billion by 2029. So, Sparc’s advancements in graphene-enhanced additives position the company at the forefront of this growing market, offering a sustainable solution to industry challenges.