Timmer has launched timIOT, a digital solution that allows monitoring and predictive maintenance of mechanical pumps.

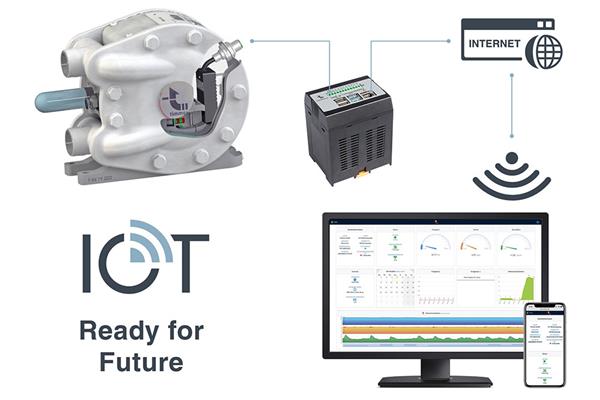

To provide operators with easily accessible operating data about mechanical pumps, Timmer GmbH – a manufacturer of products and special solutions in the field of pneumatics, pumps, vacuum technology and vacuum lifting technology – has developed tim®IOT, a digital solution which allows location-independent, real-time monitoring and predictive maintenance of mechanical pumps.

"With our new IoT solution timIOT we are facing this challenge and creating a high data availability. The solution enables the readout and statistical evaluation of comprehensive process data and can be integrated into Timmer's double diaphragm pumps and electric piston pumps, among others", explains Frederic Engels, market development at Timmer.

timIOT features a retrofittable sensor for data acquisition and timIOT smartbox, which connects the pump with the timIOT cloud platform by means of a secure transmission, for example via a separate LTE router that is independent of the company network. The visualization and evaluation of the data is done on freely selectable end devices such as PCs, smartphones or tablets. Clearly structured histograms, tables and statistics can be viewed from any location. In the case of error status or exceeding set values a notification in the IoT platform or to a defined e-mail address is made.

The importance of real-time monitoring of pumps

With the help of comprehensive data, plant operators can organize their processes more efficiently and make informed decisions, always having under control parameters such as pump frequency, number of strokes or pressure curves. Predictions on wear and tear as well as the planning of repair measures become much more precise, ensuring optimum use of the pumps over their lifetime, reduced downtime and damage, and increased process stability and machine availability.

“The statistical evaluation of the operating data also makes it easier to calculate operating costs and the optimization of system utilization," emphasizes Engels. "After all, operators often replace all pumps at the same time, even though some of them have only reached a fraction of their maximum lifetime – this costs money in the long run."

The Timmer software provides users with additionally useful tools, including intuitive maintenance planning, a maintenance calendar, a user-friendly administration of service reports and pump-specific documentations.

Timmer is offering the IoT solution based on a moderate annual license model. Regular updates and future functional expansions are planned.