The French aeronautical group relies on Cabycal to provide new surface treatment equipment to its factories in Canada and Mexico.

Cabycal will design, manufacture and install two liquid painting lines for the Lauak Group, specialised in components for the aeronautical industry. Both facilities will paint aluminium pipes and ducts and will be implanted in the factories that the French company has in Mirabel (Canada) and El Marqués (Mexico).

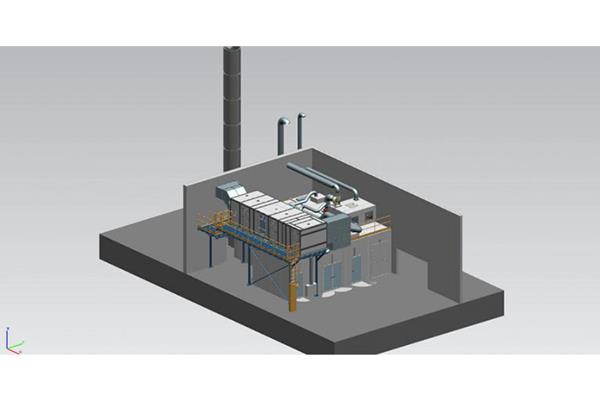

The two lines will be composed of a manual loading / unloading area, a pressurized painting booth, an evaporating zone, a polymerization oven, an aerial monorail conveyor, a mixing room and an air supply and treatment unit.

In addition, the installation is prepared to collect different values in order to create a history of them for later management by Lauak. It also incorporates a system that allows remote technical assistance to visualize the state of the line in real time and the solution of remote problems if necessary.

For Emilio Ferrando, General Director of Cabycal, this project stands out because "it forces us to continue working in the high level of technical requirement required by the aeronautical sector and to develop the equipment and facilities according to the CE and UL certification that they are what each country requires".

More and more companies in the aeronautical sector rely on Cabycal to improve their production processes. These two lines for the Lauak Group join others that Cabycal has developed for several companies in the aeronautical sector such as Sofitec and GAZC, among others.

Founded in 1975 under the name Eskulanak by its current co-manager, Jean-Marc Charrintton, the Lauak Group supplied boiler parts to Dassault Aviation. Today, the group is one of the main subcontractors for the production of primary parts, sub-assemblies and assemblies for the aerospace industry.