DXQbusiness.intelligence, Dürr's most recent addition to its DXQ digital family, provides a business intelligence application to efficiently control production processes in the automotive industry.

To ensure an efficient control of production processes, Dürr launched DXQbusiness.intelligence, a new business intelligence application for control technology. The new app allows to save information optimized for reading in a separate data warehouse, to visualize it using clear dashboards, and to create custom reports so that manufacturers always have a close eye on the availability, performance, and quality of their plants.

The key feature of DXQbusiness.intelligence is that, by separating the data warehouse from the customer's operational system, accessing the data warehouse does not cause any delays in production, unlike conventional servers which do not store data optimized for reading.

DXQbusiness.intelligence is part of DXQcontrol, Dürr's control technology for controlling plant's production. This allows the data warehouse to provide structures and tables for long-term orderly data storage across division boundaries.

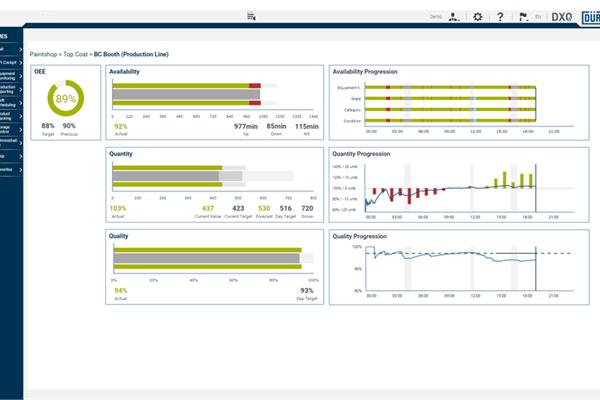

The new application from Dürr's Manufacturing Execution System (MES) displays the production data in a user-friendly dashboard, showing mission-critical data to keep production on the right track on one screen.

DXQbusiness.intelligence also allows to navigate across the entire site, limited to specific production areas or focused on individual lines to gather the necessary data for the decision-making process.

Decision-making is also aided by custom reports, which can be created and arranged according to priorities and needs. These reports allow also the monitoring and tracking of situations that require particular attention.