Dürr will be part of a joint project for setting innovative machine standards “made in Europe”.

The German engineering and manufacturing company Dürr AG has announced that it has entered a partnership with Manz AG and GROB-WERKE GmbH & Co.KG for the joint acquisition and execution of projects for equipping entire battery factories for the automotive sector. The aim of the collaboration is to take advantage of the huge growth potential for businesses involving production technology for lithium-ion batteries and to cover the entire value chain.

Under their partnership, the companies are planning to join forces and establish themselves as a European systems provider of battery production plants, offering customers a powerful alternative to existing suppliers and setting innovative machine standards “made in Europe.

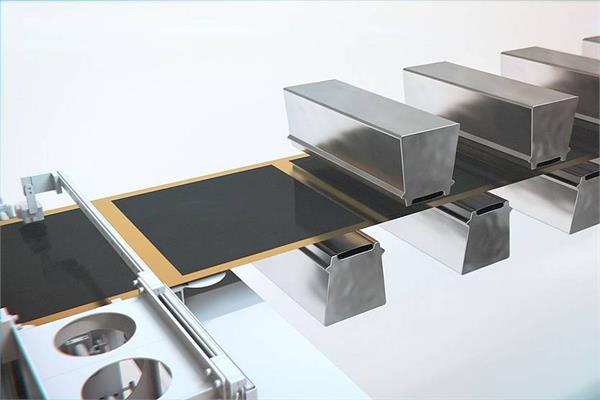

Manz AG will provide its development skills and experience in key production stages for both the manufacture of different lithium-ion cell types and their assembly into a battery module. GROB will focus on the implementation in the conception, planning and commissioning of highly complex and customer-specific plants for large-scale production. Finally, Dürr will provide its expertise in the field of electrode manufacturing and further production stages in cell and module assembly, as well as coating systems for electrodes.

“Battery production is one of the fastest-growing sectors in the European industry landscape. The rapid building of production capacity is a prerequisite for European automotive manufacturers to maintain their leading market positions in the age of electromobility. Our customers want reliable, local partners to implement their battery factories. We are taking on this challenge and are joining forces. The combined technology offering of Dürr, GROB, and Manz, stands for highly efficient manufacturing processes with maximum digitalization, a high level of availability, and excellent product quality. This enables both mass and premium manufacturers to produce exactly the right battery types for their requirements,” has stated Jochen Weyrauch, the CEO of Dürr AG.

“Manz has carved out an excellent position for itself in the battery market. We see fantastic opportunities to benefit from the dynamic development of electromobility, so we have focused our business model accordingly. We firmly believe that, based on the trendsetting alliance with GROB and DÜRR — an alliance that is unique in Europe — we have reached another important milestone toward fully harnessing the huge market potential. The cooperation agreement enables us, together with our partners, to cover the entire value chain in battery production and to considerably speed up the development of system technology for manufacturing the next generation of batteries. We are thus also helping to make Europe independent in this strategically important market of the future,” has added Martin Drasch, the CEO of Manz AG.

“We are delighted to be cooperating with Manz and Dürr, two such well-respected partners. GROB is a family-owned company that has gained comprehensive knowledge of machines, system technology, and process flows for the entire e-mobility portfolio in a very short space of time. It has now become world market leader in the manufacture of production systems for electric drives. Furthermore, in the field of battery storage technology with a focus on systems engineering, we have developed process knowledge for battery module and pack systems with pouch and hard-case cells, and we have already delivered several large-scale plants,” has concluded German Wankmiller, the Chairman of the Board and CEO of the GROB Group. “In a further consistent move, GROB has also started developing system technology for the production of battery cells. Through our cooperation with Manz and Dürr, we see ourselves in an even better position and can quickly implement large-scale plants for the international automotive industry and its suppliers. This enables us to offer solutions from a single source along the entire value chain, from coating through to pack assembly. Customers thus enjoy advantages such as high throughput, low production costs, and maximum innovative strength.”