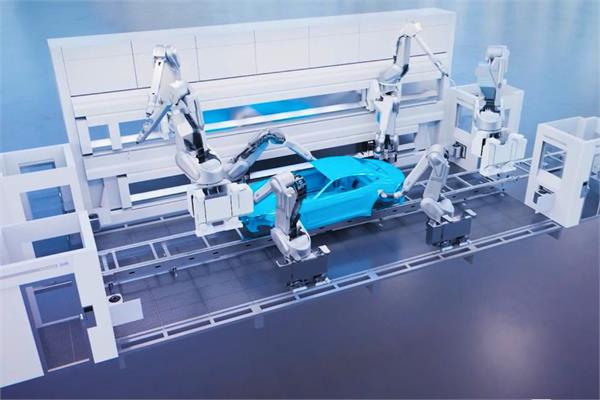

The EcoProBooth replaces conventional linear layouts with a parallel production setup, aligning with Dürr’s vision of the Paint Shop of the Future. This configuration allows for variable tact times and significantly enhances efficiency.

The multinational engineering company Dürr has once again demonstrated its innovation leadership with the EcoProBooth, a revolutionary spray booth concept that has earned the esteemed 2025 Automotive News PACE Pilot Award.

The EcoProBooth impressed judges with its modular box layout, which allows for remarkable flexibility in accommodating various car body sizes and painting processes. This innovation significantly cuts down on energy, paint and solvent consumption, positioning it as a sustainable

and highly efficient solution for modern paint shops.

“We are very proud that our technology has been recognised as a groundbreaking innovation that will be shaping the automotive industry. With 14 patent applications, nine of which have already been granted, Dürr’s EcoProBooth is positioned to transform the industry and set new benchmarks in energy efficiency and cost savings,” has stated Daniel Ackermann, Senior Manager Product Management at Dürr.

Combined with the EcoBell4 Pro atomiser generation, the EcoProBooth enables the painting of both vehicle interiors and exteriors in the same booth using either solvent- or water-based coatings. Its universal atomisers produce narrow spray patterns for interiors and wide jets for exteriors, including the application of metallic finishes. This eliminates the need to transfer car bodies between separate spray booths, saving valuable production time. Moreover, smart task distribution ensures that idle robots can perform cleaning or undergo maintenance in dedicated service cubicles located in each corner of the booth, without disrupting production flow.

A standout feature is its 95% air recirculation rate, requiring only 5% fresh air. This innovation drastically reduces both energy use and CO₂ emissions. In fact, energy consumption is lowered by up to 80% compared to wet scrubbers in conventional systems and by 45% compared to dry scrubbers in traditional lines.

Now in its fifth year, the PACE Pilot programme, organised by Automotive News, celebrates emerging innovators, from suppliers to startups, developing transformative products, software, processes, or incubator concepts. Dürr’s recognition highlights its commitment to driving the future of sustainable manufacturing within the automotive industry.

About Dürr Group

The Dürr Group is one of the world's leading mechanical and plant engineering firms with particular expertise in the technology fields of automation, digitalization, and energy efficiency. Its products, systems, and services enable highly efficient and sustainable manufacturing processes – mainly in the automotive industry and for producers of furniture and timber houses, but also in sectors such as the chemical and pharmaceutical industries, medical devices, electrical engineering, and battery production. The Dürr Group operates in the market with four divisions:

- Automotive: painting technology, final assembly, testing and filling technology

- Industrial Automation: automated assembly and test systems for automotive components, medical devices, and consumer goods as well as balancing technology solutions and coating systems for battery electrodes

- Woodworking: machinery and equipment for the woodworking industry

- Clean Technology Systems Environmental: air pollution control and noise abatement systems