Extreme Coatings has announced the rebranding of its protective solutions for feedscrews.

The international supplier of wear-resistant coating solutions Extreme Coatings has recently announced that it will rebrand its CarbideX® range of high-performance protective coatings for feedscrew applications.

The coatings, that will be presented at the Plastics Technology Expo from 29th to 31st March 2022 in Rosemont (U.S.A.), are specifically designed to optimise the performance of injection moulding and extrusion machinery.

“The new tradenames further educate the market on the company’s robust offering, providing key product delivery enhancements and easier product selection for customers. The rebranding allows us to better reach the markets that can benefit from our premium coatings and more clearly articulate the potential applications for our OEMs, distributors, and end users,” stated Scott Caplan, the Executive Vice President of Extreme Coatings.

The rebranded line includes:

- WEARPRO (formerly C1000) for glass-filled, metal-filled, and other abrasive fillers for automotive and electronic applications.

- MICROPRO (formerly C9000) formulations for calcium carbonate, silica or other sub-micron particle filled resins for bottles, housewares and sporting goods.

- EXTRUPRO (formerly Fliteguard C1000) for all extrusion applications and EXTRUPRO+ for wood flour, calcium carbonate, talc materials for composite wood decking or other filled resin extrusion applications.

- COROPRO (formerly C4000) coatings formulations are for CVP, CPVC and halogen-free polymers for pipe, electronic devices, TV screens and flame-resistant components.

In addition, the range will include the newly developed MEDPRO coatings that target medical grade polymers for plunger/syringe barrels, intravenous devices/stints and implants.

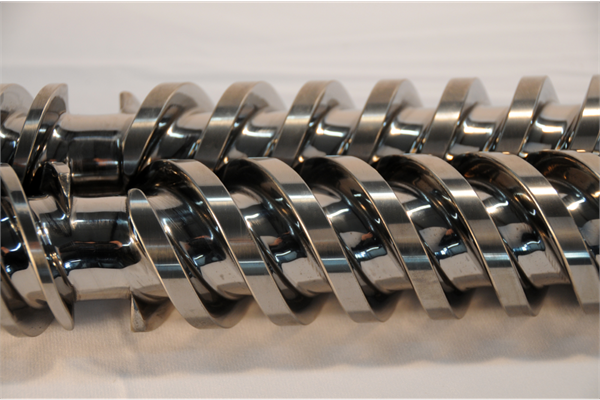

The thermal spray technology provided by Extreme Coatings applies the wear and corrosion-resistant CarbideX protective coatings made of tungsten or chromium carbide to virtually any new or repaired feedscrew. The process provides a crack- and porosity-free coating within thicknesses ranging from .004-in to .017-in per side and hardness values over 60HRc.