A team of researchers at Mercer University discovered a polymeric material that can withstand extreme weathering conditions and is capable of self-healing.

Mechanical engineering professor Dr. Alireza Sarvestani and a team of students at Mercer University discovered a novel polymeric material that can withstand extreme weathering conditions

and has self-healing properties.

Experimental studies for this new material started two years ago with a grant from a laboratory that specializes in the study of thermoplastic polyurethane, which is a rubber-like polymer with high resilience and long durability. During the past year, Dr. Sarvestani and his team did extensive testing and data analysis on thermoplastic polymers, which melt at increased temperatures and solidify upon cooling. They reinforced the polymers with various fillers, with the goal of creating unique properties that would improve the material.

They prepared numerous samples and then put them to test by stretching, cutting and heating them. They also put some of the samples through an accelerated weathering machine prior to running those tests. They found success when one particular sample demonstrated self-healing and weather-resistant capabilities.

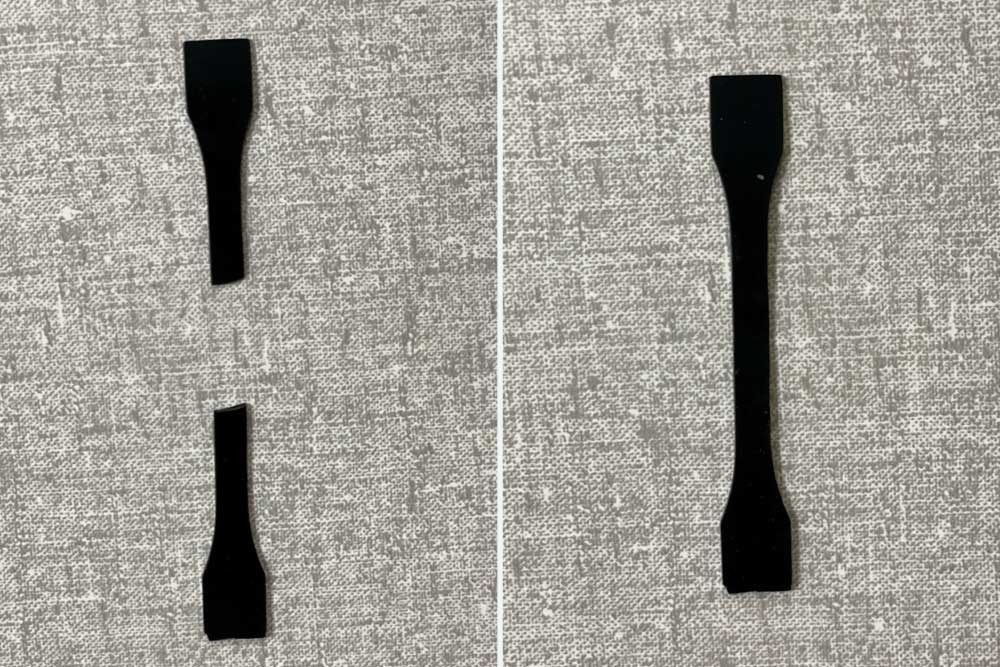

“We prepared a film of the material, and broke it into two parts. We increased the temperature, and at 60 or 70 Celsius, it actually started healing,” Dr. Sarvestani said. “Now we have a material whose property is almost exactly the same as before melting. By increasing the temperature locally, you can heal all the damage done. The other interesting property is it’s a very resistant material against UV radiation.”

The material weakened only slightly after healing and still proved to be quite strong after undergoing the same force tests.

At left, the material is shown after being cut in two. At right, the material is shown fused back together upon being heated. (Photos provided by Dr. Sarvestani and Daniel Krashin)

At left, the material is shown after being cut in two. At right, the material is shown fused back together upon being heated. (Photos provided by Dr. Sarvestani and Daniel Krashin)Potential application fields

Dr. Sarvestani said the material is ideal for coating purposes, especially for aerospace vehicles and watercraft. For instance, pieces of an airplane could potentially be coated in the material to protect it from damage from debris in the air and UV exposure. The material could be used on ships to prevent water corrosion. And if damage or abrasion did occur, the material could be repaired by increasing the temperature.

What’s next

Dr. Sarvestani plans to submit the research findings for publication in high-impact journals this summer and then apply for research grants.

Next up, his team will conduct further testing and begin to look at ways to improve other properties of the material. He hopes to eventually partner with researchers from other fields, such as chemistry, to take the research further and make the project more sustainable long term.

The next phase of the project will include testing the material on a larger scale and trying to make the polymer conductive by mixing it with materials like silver or gold.