Sustainability and safety are two key drivers in the printing ink industry which inspire innovation. Inks with high bio-renewable content are in demand across numerous end-use applications. Evonik Coating Additives has developed safe & sustainable defoamers – without sacrificing performance.

Historically, strong and effective defoaming in waterborne inks has been synonymous with siloxane-based products. To leave the choice of chemistry to our customers, our approach was to develop siloxane-free defoamers exhibiting similar defoaming properties, while also providing a bio-renewable content >50% and complying with the highest regulatory standards and global food contact regulations.

Therefore, a screening approach combined with statistical methods was chosen to develop two new defoamers. Potential interesting natural raw materials were identified and screened in a Design of Experiment (DOE) way to understand the interactions. Synthetic components were tailored to achieve optimum performance of the resulting defoamers.

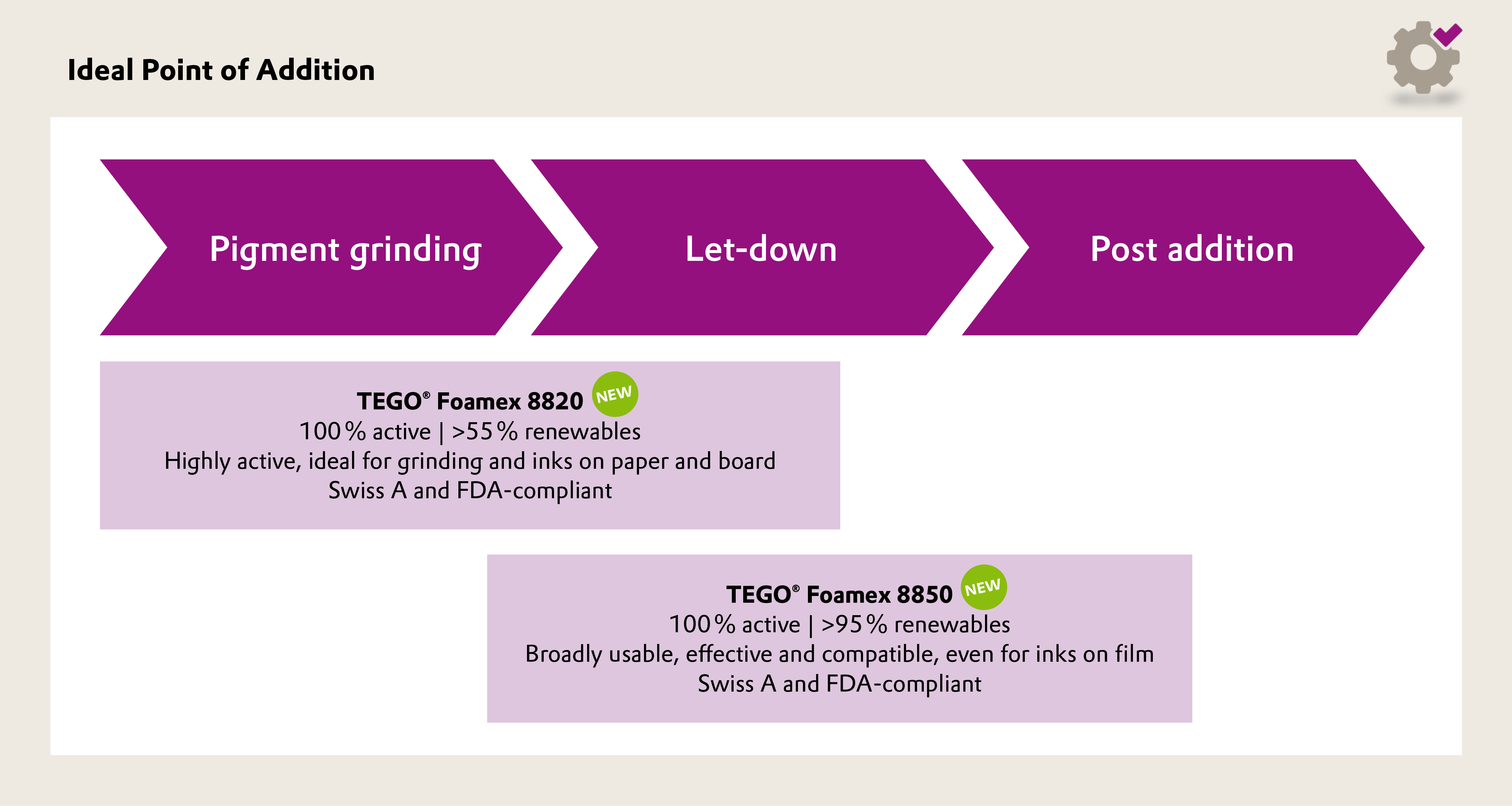

As a result, we obtained two high performance defoamers, one targeting addition to the grinding stage, the other to the let-down stage.

Our new defoamer concentrates TEGO® Foamex 8820 and TEGO® 8850 perform on eye-level with standard siloxane-based defoamers.

These two new defoamers differ in defoaming power and compatibility. TEGO® Foamex 8820 is very powerful and shear stable, ideal for use at the grinding stage.

TEGO® Foamex 8850 provide utmost compatibility and easy incorporation making it ideal for addition at the let-down stage or post addition.

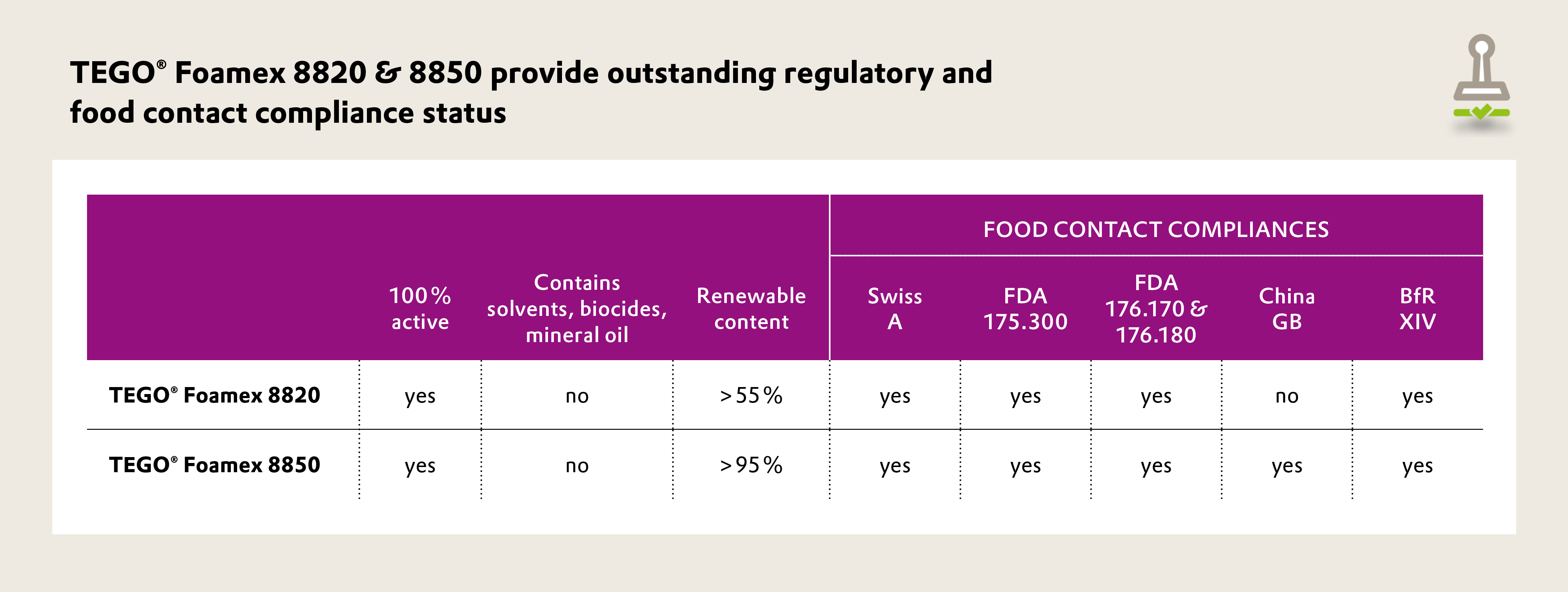

Of course, both products exhibit great food safety regulation compliance as seen in below table.

If you want to know more, please visit our COATINO® Campus. Here you can find more detailed information in our online course “TEGO® Foamex 8820 and 8850 for WB inks and varnishes”.