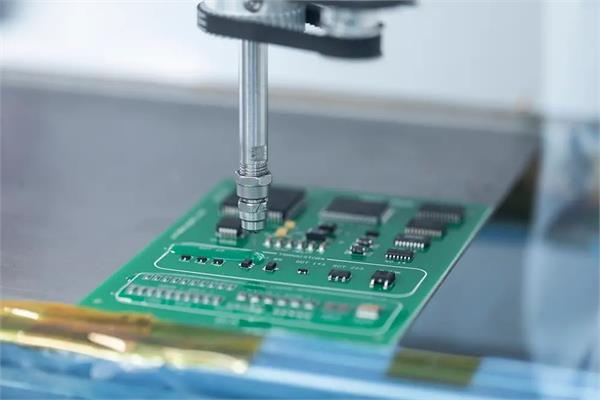

The newly-developed coating of Henkel can protect the industrial electronic components subjected to extreme environmental conditions.

The multinational Henkel has launched Loctite Stycast CC 8555, a coating designed to protect electronic components in extreme environments. As a matter of fact, the new solution can safeguard the printed circuit boards (PCBs) and sensitive components in demanding, high-power applications, such as motor drives, PLCs, electric vehicle charging infrastructure, AC/DC power supplies and other high-voltage electronic devices.

“High-power electronics are integral to industrial manufacturing, human mobility and comfort, and global energy production. These systems must adhere to the highest reliability and safety standards; protecting electronics is vital to their dependable function and longevity. Conformal coatings are the go-to protective material for nearly all PCBs used in power electronics, and Henkel’s latest formulation rises above. It delivers on the reliability requirements foremost, but is also easy to use, cost-effective, and lower-impact material. Loctite Stycast CC 8555 covers all the bases and then some,” has stated Justin Kolbe Director of Market Strategy for Power and Industrial Automation at Henkel.

Loctite Stycast CC 8555 offers good resistance to adverse weather conditions, such as humidity, gas mixtures and various chemicals. In addition, it has a relative temperature rating of 130°C per UL 746E standard, a UL 94 V0 flammability rating and meets IPC-CC-830 requirements. This solution is essential for protecting industrial equipment, power conversion systems and alternative energy infrastructures, which need to be reliable and durable.

“Loctite Stycast CC 8555’s VOC- and solvent-free formulation answers the call for environmental concerns and provides significantly lower cost from a surface area perspective. With solvent-borne conformal coatings, three to four times the weight must be deposited to achieve the same thickness as non-solvent-based materials. This means Loctite Stycast CC 8555 can provide exceptional protection with one-third to one-half of the sprayed volume of a solvent-based system. Users get lower total cost, environmental volatiles reduction, energy-saving curing, and superior performance. That’s a hard combination to beat!” has added Kolbe.

Lastly, Loctite Stycast CC 8555 is cost competitive

with solvent-based formulations and provides wetting, flow and levelling performance – thus ensuring rapid and complete coverage of PCBs and components sensitive without voids or visible defects. Curing is achieved quickly, with primary UV curing occurring within seconds, followed by moisture curing for shaded areas.