Lesta PAINT STUDIO 3.0 enables the continuous optimisation and personalisation of the coating process even after the path has been acquired.

Lesta has recently announced the new version of its innovative software Lesta PAINT STUDIO, an advanced offline programming system for robotic painting arms. The major innovation of the new 3.0 version is the ability to modify acquired trajectories, ensuring flexibility to optimise the coating process and reducing production time and costs.

Coating large products such as components for boats, agricultural vehicles and tractors presents a significant challenge. In addition, the difficulty of finding skilled personnel and the need to optimise the production processes is leading companies towards automation.

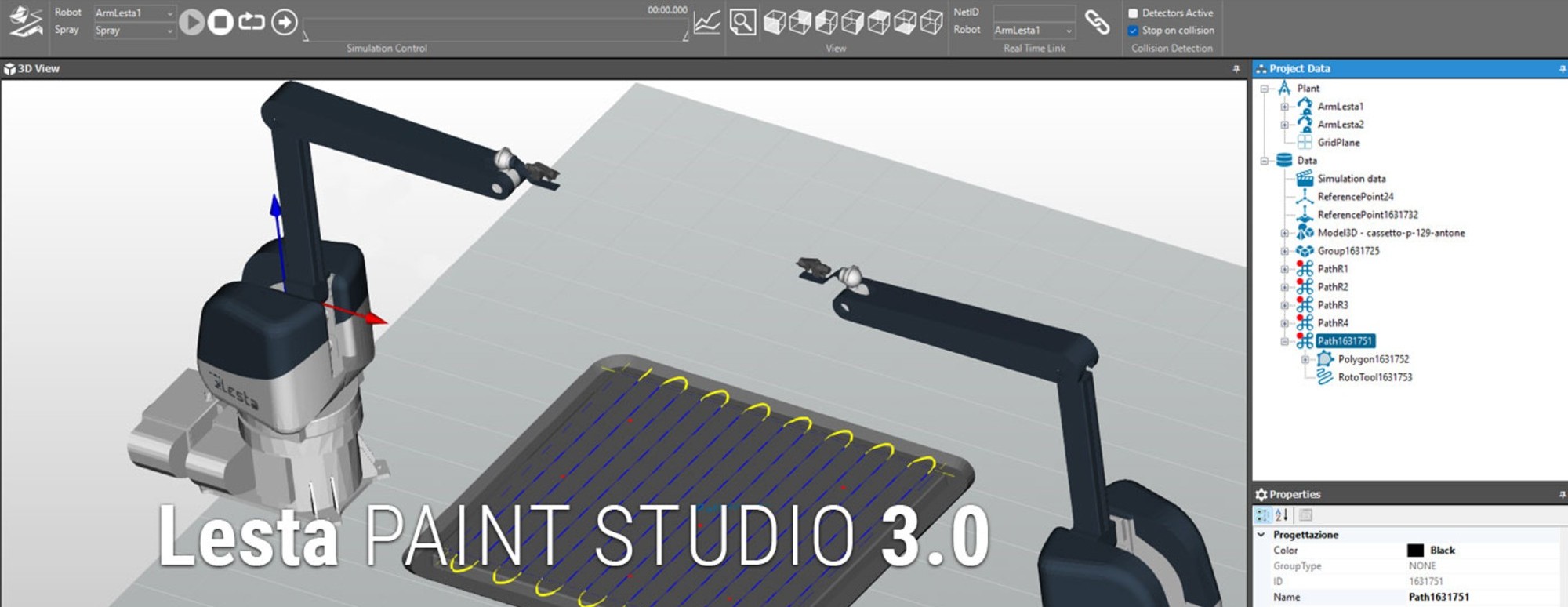

The updated Lesta PAINT STUDIO 3.0 system offers an effective solution, enabling businesses to programme painting paths directly from the technical office and without requiring a specialised operator. Through the advanced CAD CAM software, that has been specifically developed for robotic coating operations, it is possible to set precise and efficient programming by creating coating paths within an interactive 3D environment that simulates the entire process – achieving high quality without sacrificing operational flexibility.

The system allows to modify the paths recorded by the robot during its self-learning process, by letting users intervene and modify certain parameters (such as the distance of the spray gun from the surface or the application angle) without altering the originally recorded trajectories.

So, Lesta PAINT STUDIO 3.0 enables the continuous optimisation and personalisation of the coating process even after the path has been acquired, providing companies with unparalleled flexibility. As a matter of fact, it ensures improvements in painting quality and efficiency without the need to reprogramme the entire cycle or perform additional manual recordings. Moreover, the ability to make quick and precise adjustments greatly improves production times and reduces operational errors.