Mipelon UHMW-PE fine powder from Mitsui Chemicals provides an effective alternative to PTFE for improving abrasion resistance in paints and coatings.

The spherical UHMW-PE fine powder from Mitsui Chemicals Europe Mipelon can offer a high-performance substitute for PTFE – thus enhancing abrasion resistance and chemical resistance in paints, powder coatings, water-based coatings and solvent-based coatings, as well as rubber-coated rollers, automotive rubber profiles, and anti-blocking agents for films.

While the lower melting temperature of UHMW-PE (around 135 °C) limits its use compared to PTFE, Mipelon is effective at temperatures up to 120 °C, with the PM200C grade able to withstand temperatures up to 200 °C in hydrocarbon oils. Unlike PE powder, Mipelon does not swell at higher temperatures and maintains its shape and function.

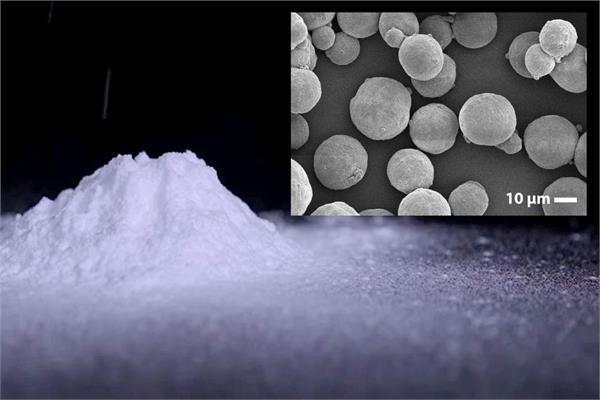

Moreover, Mipelon delivers a lower coefficient of friction and improved abrasion resistance at the same dosage compared to PTFE, offering a cost-effective solution. With a density of 0.97 g/cm³, which is about half that of PTFE, it also contributes to weight reduction. Its molecular weight is around 2 million g/mol, and its spherical particles are notably small, with an average particle size (D50) of around 10 µm for the PM-200 type. Other grades, such as XM-220 and XM-330, have D50 values of 30 µm and 65 µm, respectively. The finer powders are ideal for paints and coatings.

Lastly, Mipelon’s smooth, spherical particles and narrow particle size distribution enable excellent dispersion, outperforming PTFE in terms of lower friction and abrasion, even under long-term stress. Mipelon also demonstrates superior chemical resistance to acids, alkalis, organic chemicals and absorbs minimal moisture.