Infragas’ integration of RHT burners and catalytic technology is the ideal solution for combining dry-on-fused powder coating performance, energy savings, and reduced environmental impact. Vermobil Style’s choice is proof of this. As a company that has been designing and manufacturing outdoor furniture and accessories since 1993, it searched for the most effective solution to raise the quality bar, speed up its coating process, and make its production even more sustainable.

Dry-on-dry powder coating, the most common powder application technology, calls for the intensive use of energy resources to cure the base coat and then the top coat. For several years now, an additional step called gelling has been added to the coating cycle to overcome this problem, which returns the base coat layer applied on the substrate to a molten state through infrared heating; afterwards, the part enters the oven for final curing, initiating the process known as “dry-on-fused” precisely because the pre-cured coating is melted and not fully baked, thus avoiding a double curing step. Integrating the gelling phase also results in a coating layer that gives the substrate higher corrosion and UV-resistance properties, making it ideal for all products intended for outdoor use, such as those manufactured by Vermobil Style Srl (Marsciano, Perugia, Italy). The company, celebrating its 30th anniversary this year, designs and manufactures outdoor furniture and accessories in line with contemporary trends to meet the most advanced design requirements.

“What we do here,” says one of the founding partners, Mauro Baiocco, to present its business, “is making outdoor spaces more comfortable and liveable thanks to our furniture and accessories made in durable, premium materials, created with functionality and style in mind, and characterised by a refined combination of lines and colours. The attention we pay to green spaces and nature in general is also reflected in the standards we adopt to ensure fair, environmentally friendly production processes, also protecting the safety of our employees and geared towards providing durable, high-performance finishes.” In fact, coating objects or structures intended for outdoors involves a more complex process than those intended for indoor use. “We have carefully improved each phase of our coating cycle because even though this is our final production step before assembly and packaging, it is responsible for the appreciation of our furniture nationally and internationally. Therefore, we started by perfecting the pre-treatment phase and then optimising the gelling phase before curing, which we have been carrying out for over 12 years with Infracat® catalytic panels, to which we have recently added a series of RHT gas radiant burners. Infragas Srl (Mappano, Turin, Italy) supplied us with both technologies.”

The history of Vermobil

The Umbria region, where Vermobil was established and developed, has always been an important district for the furniture industry. “In 1993 there was the beginning of the adventure of our company, founded to offer a contract coating service for metal furniture, although it soon moved on to manufacture its own products thus meeting the needs of an increasingly demanding market. In 1995, the major players in the sector gathered, first, at the SPOGA fair in Cologne (Germany) and, then, at the Sun trade fair in Rimini (Italy), the most important outdoor furniture exhibitions in Europe at that time. Our presence at these events enabled us to make a breakthrough in the Swiss market and begin to distribute our products throughout the DACH market, as well as in Italy.”

The success of its furniture and accessories also enabled Vermobil to grow in size. “Our original factory occupied an area of about 4,000 m2, to which another hall of 2,000 m2 was soon added. Both the facilities were addressed to the production department. "In recent times, an additional building spanning 7,000 m2 has been acquired for shipping warehouse and offices purposes. The three buildings currently house a total of 60 employees."

Today, the company’s main target market is Italy and its core business is outdoor furniture for the contract industry, especially for bars and restaurants. “We have established important partnerships with leading outdoor furniture companies. Our collaboration with them also raises the reputation of the products marketed under our own brand name, which can now be found in the high-end design segment.”

Care at every production stage

From the purchase of raw material, consisting mainly of carbon steel and aluminium, to final shipment, the entire production process takes place in-house, except for cold galvanising, which is outsourced. When they go back to Vermobil’s factory, components have already undergone degreasing, perfected with a pre-treatment process, followed by drying, base coat application in a booth designed and installed by Siver (Corciano, Perugia, Italy), gelling in an Infragas IR oven, top coat application in a quick-colour change booth equipped with Nordson dense phase guns (of which Siver is the exclusive dealer for Italy), and final oven curing.

“For about a year now,” says Baiocco, “we have been using the one-stage product Toran 3 supplied by Chemtec (Corbetta, Milan, Italy) in our pre-treatment process, after numerous tests carried out with an in-house large-sized salt spray test device capable of accommodating up to 3 chairs. This multi-metal product is suitable for both iron and aluminium, a valid alternative to phosphodegreasing or phosphating followed by passivation. As the product dries, it deposits a very thin, continuous, three-dimensional conversion film that promotes paint adhesion and increases the corrosion protection performance of the coating system. The organic polymer film obtained encapsulates the oily contaminants on the workpieces, trapping them in the three-dimensional structure of the polymer formed on the metal, thus avoiding waste generation and converting the contaminants into an active part of the process. The result of the pre-treatment stage is functional to the aesthetic performance of the coating system, as well as to the environmental friendliness of our manufacturing operations: Toran 3 does not generate any emissions or waste to be disposed of.”

The oven installed in Vermobil’s paint shop is used for both drying after pre-treatment and curing. “To avoid any risk of contamination, we compartmentalised it. On one side, the burner feeds the oven for drying up to a temperature of 150 °C. On the other side, our Qualicoat class 1 and 2 polyester thermosetting powders are subjected to the final curing stage at 190 °C for 15/20 minutes.”

The infrared gelling system’s upgrade

Vermobil has been using infrared technology for powder gelling since 2012. “Previously, we were forced to pass our parts through the curing oven twice, which meant a considerable waste of energy and time,” emphasises Baiocco. “The installation of the Infragas oven was such a turning point in our production flow that 10 years later, we decided to upgrade its technology with the integration of RHT burners.”

“The first equipment provided to Vermobil,” indicates Francesca Marabotti, Business Development & Marketing Manager at Infragas Srl, “included 20 catalytic panels from the Infracat® series, a name chosen by our team to emphasise the combination of infrared energy and catalytic technology. With a surface temperature that can be adjusted from 180 to 550 °C and a power output ranging from 1.5 kW (1290 kcal/h) to 17 kW (14617 kcal/h), these panels are designed to develop a power density of 20 kW/m2 at a medium to long wavelength (2 to 10 μm). This guarantees infrared radiation that is, first of all, safe thanks to the absence of flames and, secondly, effective because the prolonged permanence of the electromagnetic wave on the parts’ surfaces results in better absorption by the organic material, leaving the characteristics of the substrates unaltered. In this specific case, the panels supplied to Vermobil belong to our 18.60 Infracat series and have a power range of 7.2 to 12 kW.”

“In 2022, after 10 years of truly satisfactory use,” explains Baiocco, “we decided to test the Radiant High Temperature (RHT) technology. We visited Infragas’ test centre together with a team from Siver, our long-standing plant engineering partner, to assess the results we could achieve by implementing a new RHT radiant burner section.” Following the tests, the company opted for adding a section of 3 RHT burners, 2 7C vertical ones and one 7L floor one, for a total installed power of 210 kW and manageable power up to 105 kW, in order to achieve a better powder curing performance.

“Infragas’ RHT gas radiant burners are infrared, pre-mixed gas systems that reach a surface temperature of 950 °C,” illustrates Marabotti. “They are a safe and reliable source of heat generated by burning natural gas or propane, transmitted through short-wavelength infrared rays. The structure of Radiant High Temperature burners is made of stainless steel for excellent robustness over time. Each burner has a control and pre-mixing unit for properly mixing air and gas. The micro-flame combustion on metal surfaces produces extremely low amounts of NOx, carbon monoxide, and unburnt emissions, an important factor from an environmental and safety point of view.”

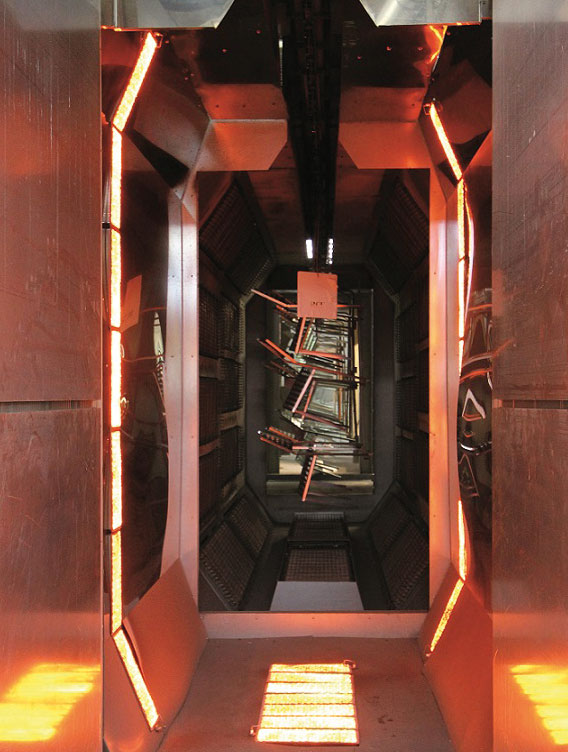

The inside of the oven with the 22 Infracat® catalytic panels. © ipcm

The inside of the oven with the 22 Infracat® catalytic panels. © ipcm

The RHT burner section integrated in 2022. © ipcm

The RHT burner section integrated in 2022. © ipcm

The advantages of the new hybrid system

“With the parts dwelling in the oven for just 3 minutes and the double curing stage being eliminated, the advantages of catalytic technology were already obvious in terms of energy and time savings, but today, thanks to this hybrid system, we have further improved our coating quality,” confirms Baiocco. “The integrated RHT burners increase the effectiveness of radiation, enabling all-round heating of the entire surface of each component. This prevents the base coat layer from surfacing after the top coat has been applied. To avoid this problem, we were previously forced to apply dark top coats on dark base coats and light top coats on light base coats. Now, we can use only one monochrome base coat regardless of the colour of the top coat, with excellent results that are also highly appreciated by our customers in Northern Europe – who differ from the rest of the market in the strictness of their finishing specifications, as outdoor furniture is put to the test by the harsh weather conditions of those geographical areas. Saving energy and increasing the speed of the coating cycle also enables us to offer an even more sustainable production flow.”

Sustainable infrared catalytic technology

“Infrared radiant panels use catalytic gas oxidation technology to emit heat in the form of infrared rays,” adds Marabotti. “As a result, they can heat the material’s surface alone, improving the production process’ overall efficiency. They are equipped with a highly effective catalytic converter that allows achieving high temperatures with low electrical power consumption during the pre-heating phase, thus ensuring energy savings. In some cases, when treating parts such as cylinders or tanks that can turn on themselves 360°, our IR ovens can replace conventional hot-air ovens by reducing curing times by at least 3 times. In the case of Vermobil, we developed a system to speed up the coating cycle that was also endorsed by plant engineering company Siver.”

“Siver has been working with Vermobil since 1993, the year of its foundation,” says Marcella Baldoni, the owner of this Perugia-based company, “and has always affirmed the effectiveness of catalytic and RHT technologies, so much so that it immediately validated the hybrid system tested at Infragas. Since 2014, Siver has been the exclusive dealer for Nordson equipment in Italy, and this partnership has enabled us to provide our customers with an even more innovative range of products.”

“Siver supplied Vermobil with its first coating booth,” notes Baiocco. “Since then, mutual trust has been the basis of our 30-year collaboration. It was its owner, Luca Tomassoni, who suggested we contact Infragas to solve our coating problems. Its excellent consultancy service and the geographic proximity between our companies enable its team to intervene quickly for any critical issues. They provided us with advanced and flexible coating equipment, suitable for new future products.”

Manual top coat application with a Nordson gun. © Siver

Manual top coat application with a Nordson gun. © Siver Vermobil’s furniture and accessories must withstand harsh weather conditions like those in northern European areas. © Vermobil

Vermobil’s furniture and accessories must withstand harsh weather conditions like those in northern European areas. © VermobilAs a company specialising in high-end outdoor furniture,” concludes Baiocco, “the natural environment is precious for us, and surrounding ourselves with reliable partners whose solutions enable us to minimise our impact is equally essential. From the choice of pre-treatment chemicals to gelling and curing technologies, up to powder application equipment, Vermobil has further confirmed its focus on protecting the environment and greenery, without which our products would have no reason to exist.”