AkzoNobel will take part in a joint project to improve the durability, functionality and recyclability of coatings, thin films and inks.

The international paints and coatings manufacturer AkzoNobel

has recently announced that it has joined other eighty-one companies, businesses and social organisations in the major Dutch research programme ‘Perspectief’, focused on developing new technologies that will help solve some societal challenges.

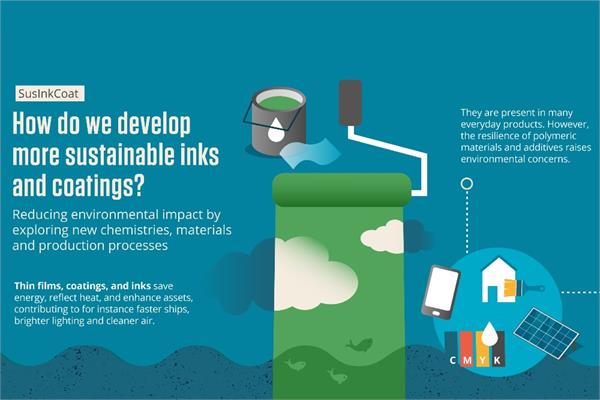

The company will cooperate together with private partners and other societal stakeholders in the government-funded SusInkCoat project in order to develop new materials, processes and applications to improve the durability, functionality and recyclability of coatings, thin films and inks.

“Our discussions about collaborating with our SusInkCoat partners have been very positive. We are all facing the same societal challenges – how to become more circular – and we are looking for the same solutions in different application areas. But we have never done that together for this specific research topic, so we need an ecosystem to help us solve these challenges,” has stated André van Linden, the director for research and development of AkzoNobel and co-lead of SusInkCoat.

The programme, which will run for the next five years, is backed by the Ministry of Economic Affairs and Climate Policy and the Dutch Research Council (NWO). AkzoNobel will be collaborating with Canon, Evonik, GFB, PTG and RUG Ventures, who together possess extensive knowledge of market demands, supply chains and production processes. All the SusInkCoat partners will also work with academic researchers at several Dutch universities in an effort to identify promising developments that can be commercialised, used for education purposes or for outreach to the public.

“The programme, one of many R&D projects we are involved with, will also support our ambition to achieve 50% less carbon emissions in our own operations and across the value chain by 2030. We want to make the recyclability of materials – such as furniture, building materials and steel constructions – easier by introducing functionalities like self-healing, higher durability and triggered release The more you can leave the materials in their original state, the more sustainably you can operate,” has concluded van Linden.