The Defense Threat Reduction Agency’s Chemical and Biological Technologies Department is developing a new coating that can temporarily shield tactical military equipment from chemical warfare agent (CWAs).

The DTRA’s Chemical and Biological Technologies Department in its role as the Joint Science and Technology Office (JSTO) for the Chemical and Biological Defense Program is testing a variety of new temporary coatings that are compatible with painted military surfaces to repel chemical warfare agents (CWAs).

Current military equipment coatings provide visual camouflage and corrosion protection but still require enhanced resistance to CWA penetration. This is why the DTRA-JSTO is collaborating with the U.S. Combat Capabilities Development Command Chemical Biological Center (DEVCOM CBC), U.S. Naval Research Laboratory, U.S. Army Research Laboratory, and industry partners to develop and test temporary overcoats that can be sprayed, wiped, or brushed on equipment by war fighters and last a minimum of six months in the field.

Recent tests on this new coating showed a reduction in the amount of absorbed CWA by fivefold to a hundredfold, and the coatings remained effective beyond eight weeks in normal environmental conditions. Researches expect that these coatings will significantly improve CWA resistance by a minimum of tenfold and be durable enough to withstand harsh field environments and decontamination procedures without degrading or compromising the essential properties of the underlying coating.

Why CWA-resistant coatings are important

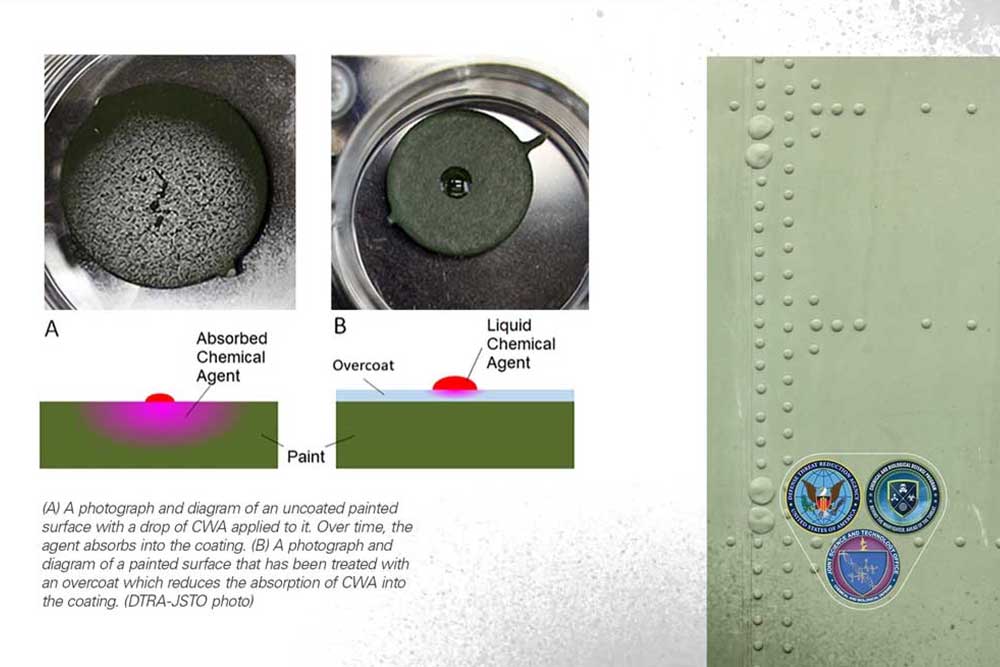

After exposure, CWAs may penetrate coatings and be absorbed before the equipment can be effectively decontaminated.

An ideal military equipment coating would reduce surface penetration by CWAs to decrease the required time and resources for effective decontamination, which would allow war fighters to rapidly resume the mission. Because most decontaminant solutions are water-based, they don’t effectively penetrate coatings where absorbed CWAs may be hiding. The longer absorbed agents reside on the surface, the more difficult they become to remove and decontaminate, and they may also represent a persistent contact and vapour hazard as they slowly evaporate out of the coating, a process called off-gassing.

Researchers are harnessing modern advances in polymer synthesis, engineering, and coating formulations to enhance the CWA resistance and improve the decontamination process of painted military surfaces down to the stainless-steel level.

The testing methodology

To assess properties of candidate temporary coatings, DEVCOM CBC validated a test standard called the Chemical Agent Resistance Method (CARM) that measures the amount of CWA retained by a material after the agent penetrates the surface or coating for specific amounts of time. After a standardized water rinse and soapy water wash, the retained agent is measured using solvent extraction.

The advantage of this new method is that it reflects the decontamination processes used in the field and quantifies agent retained within the painted surfaces.

CARM will be used to compare and quantify CWA resistance of both current and future coating systems.