Powder coatings users will have all the necessary information at their disposal at any time in order to pass a quality audit or an inspection, fill out a technical specification, or respond to a dispute.

We live in the era of the fourth industrial revolution, of the digital revolution, of Industry 4.0. Yet, companies are still required to produce mountains of paper. Be it to comply with the new privacy regulation or to perform a quality audit, it seems impossible to avoid generating a huge amount of paper documentation.

Nowadays everything is just a click, scroll, or swipe away. Billions of pieces of information are available on our mobile devices: knowing the basics of keyword or hashtag searches is enough to find anything in a few seconds. Yet, classifying the coated products of a warehouse can still be a time-consuming and burdensome operation.

Getting the data you need at the right time, always having the updated version of a document available while avoiding to produce further paper documentation and to flood your suppliers with requests, or simply choosing the product you want with one click is now possible with the brand new APP of Adapta for all powder coating users.

Adapta Color SL is very attentive to all safety and prevention-related issues as tools to protect the integrity and health of people interacting towards the sustainable development of their business. Information and training are key elements for achieving these goals. The new ADAPTA APP for mobile devices is the result of Adapta's efforts to comply with all the requirements established by the Regulation (EC) No. 1907/2006 (see note 1) concerning the Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) and the Regulation (EC) No. 1272/2008 (see note 2) Council on Classification, Labelling and Packaging of substances and mixtures (CLP) and its subsequent amendments. This tool, a pioneer in the powder coatings market, makes the latest versions of safety data sheets (SDS) and product analysis bulletins available in real time. The user simply has to scan the barcode of the box containing a product and select a language. In this way, powder coatings users will have all the necessary information at their disposal at any time in order to pass a quality audit or an inspection, fill out a technical specification, or respond to a dispute.

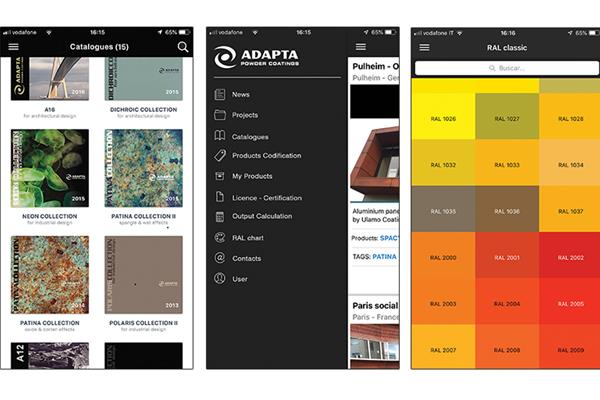

The application has a wide range of additional features, such as the calculation of the theoretical yield of specific coating products, the coding scheme of all products available for sale, and the list of Adapta's licenses and (business, product, and environmental) certifications. The APP also offers an overview of Adapta's activities and products: colour ranges, smart coating catalogues, flagship projects with the description of the finishes used, latest news, and much more.

The "RAL Classic" section enables the user to click on a colour code to verify its name in 5 languages, its RGB composition, and the list of Adapta products available for that tint. Finally, the "My products" section allows the users to create a digital archive of all Adapta products available in their warehouse. By scanning the barcode on the powder boxes, the APP creates a record with the related technical data and an icon corresponding to the colour of the scanned product.

This amount of information available in real time on mobile devices will enable users to find the information needed at the right time, saving paper and archiving times.

Complete and continuous traceability of powders, simplified warehouse management, and real-time availability of technical information on products: these are the key advantages of ADAPTA APP, without forgetting accessibility – because, nowadays, being user-friendly is a must.

//Note 1: Regulation (EC) No. 1907/2006 of the European Parliament and of the Council concerning the Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH).

Note 2: Regulation (EC) No. 1272/2008 of the European Parliament and of the Council on Classification, Labelling and Packaging of substances and mixtures (CLP).//