Zircotec's research on ceramic coating development aims to enable the use of lightweight materials in electric vehicle battery housings and cooling plates.

Zircotec has secured significant government funding through the Advanced Propulsion Centre UK (APC) to develop a single proprietary ceramic coating that will unlock the use of lightweight materials, including aluminium, across EV battery enclosures and cooling plates.

The battery cases of today's electric vehicles are made of heavy-duty steel. Therefore, to reduce the weight of electric vehicles and improve their range, alternative, lightweight materials such as aluminium and plastic composites are required. Furthermore, the efficiency of aluminium cooling plates within the battery pack is hampered by the required electrical insulation and the typically low level of thermal conductivity. It is possible to improve the efficiency of cooling plates by means of thin, high-performance electrical insulation with higher thermal conductivity.

“The key to unlocking the use of new, lightweight materials across battery enclosures and cooling plates in EVs is being able to develop and effectively apply high-performance coatings that ensure the safe thermal and electrical operation of the substrate. The Advanced Propulsion Centre CeraBEV advanced route to market demonstrator project allows our engineers to develop world-first, all-in-one dielectric and flameproof ceramic coatings that will address and overcome the significant thermal management and electrical insulation challenges associated with the lightweight materials OEMs want to use on their vehicles,” has commented Dominic Graham, Zircotec Engineering Director.

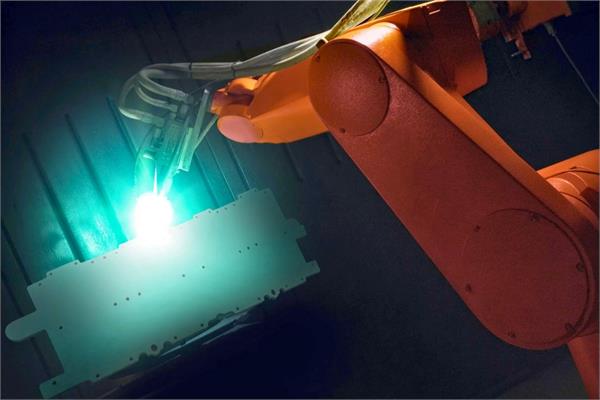

To realise the research, Zircotec will develop its existing range of ElectroHold® coatings to provide high-performance dielectric, flame-retardant and EMC shielding properties. These products are lightweight, fit easily into existing automotive design infrastructures, protect against water ingress, corrosion and chemical attack, as well as provide maximum performance and adhesion levels during normal operating conditions.

“We’re delighted to be selected to receive this APC funding which will not only enable Zircotec to extend its current ceramic coating expertise within the EV sector, but will also accelerate the UK’s battery energy storage technology capability through ceramic coating research that has the power to transform material use in the battery electric vehicle sector,” has stated Andrew Donachie, COO of Zircotec.

“Our skills and experience in developing thermal management solutions for OEMs and top-flight motorsport, including F1, are well known. But the Electric Vehicle market is an area we’ve been focusing on heavily during the last 12 months by developing out our current thermal science so a new breed of ElectroHold solutions. This proven technology will provide the platform for our work towards delivering the CeraBEV project,” has concluded Graham.