The Louvre Abu Dhabi attracts millions of visitors every year. Located on Sa'diyyat Island, its building is considered a unique piece of architecture. This article explores how the Abu Dhabi museum of art and civilisation was built and painted.

Inaugurated on 8 November 2017, the Louvre Abu Dhabi is a museum of art and civilisation created through a thirty-year agreement between the UAE capital and the French government. Designed by award-winning French architect Jean Nouvel within the vast cultural and recreational complex of Sa'diyyat Island, it was conceived to create unity and dialogue between different cultures, or better to “look at humanity in a new light”. It is no coincidence that the museum’s essence is embodied by the large perforated dome that protects the building and from which sunlight filters in.

For his project, one of the most important and advanced not only for the Emirates capital, but for the entire world, Nouvel drew inspiration from traditional Arabian architecture, skilfully combining it with contemporary design elements and cutting-edge engineering solutions.

The Louvre Abu Dhabi is actually a museum-city by the sea consisting of 55 buildings connected by different routes and housing twenty-six permanent galleries, a temporary exhibition space, the Children’s Museum, an auditorium, several restaurants, a boutique, a café, and a history centre. The façades of the individual buildings are made with aluminium and 3,900 panels of Ultra High Performance Concrete (UHPC).

The huge dome, with a diameter of 180 metres, protects a large part of the buildings (a total area of 24,000 m2). It is composed of eight different layers: the four outer layers are lined with stainless steel, whereas the four inner layers are lined with aluminium. A steel frame separates the different layers from each other.

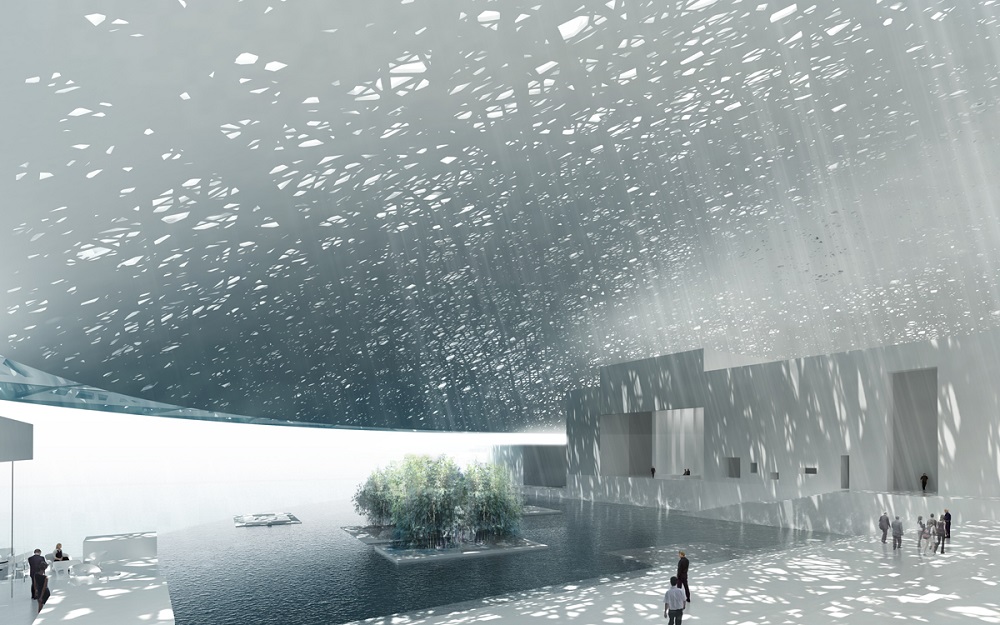

The dome’s special feature is the complex geometric pattern that is created by the overlapping layers and 7,850 aluminium stars of various sizes and with different angles, which let the sun’s rays penetrate the structure creating evocative plays of light also called “rain of light”.

The rain of light created by the dome’s geometric pattern. © TDIC, Design: Ateliers Jean Nouvel

The rain of light created by the dome’s geometric pattern. © TDIC, Design: Ateliers Jean NouvelThe dome, which weighs over 7,500 tonnes, is supported by four concrete and steel pillars, which are located 110 metres apart and concealed within the buildings that make up the museum complex: an engineering choice that creates a floating effect and conveys a sense of lightness.

The dome was designed with a completely green approach. In fact, it acts as an awning protecting the central square and some of the buildings against the strong solar radiation and high temperatures to which Abu Dhabi is exposed; such shade reduces the energy consumption of the entire structure. The use of air conditioning to heat the museum is also reduced.

Moreover, thanks to passive energy conservation techniques and HVAC systems, a peculiar microclimate is created within the area protected by the dome, regulating its own interior temperature.

The architectural project, which cost around €600 million, has received several prestigious international design and sustainability awards.

The importance of coating

An integral part of the Louvre Abu Dhabi’s construction was the painting phase, which played a crucial role both in giving the structure an aesthetics degree worthy of a project of this magnitude and in protecting it against the weather conditions of the Persian Gulf and exposure to water.

The entire building is located 11 metres above sea level and the highest point of the dome is 40 metres above sea level. Water is the common thread linking the various buildings and what makes this museum unique. However, it can also become a major enemy of architectural structures as it generates moisture and corrosion. It is therefore essential that buildings are optimally protected. In the following paragraphs, we will take a look at the different types of coatings used to treat one of the world’s most important museums.

Heat reflective paints

The buildings’ façades, made of aluminium and UHPC concrete, were coated with heat reflective architectural powder coatings

specially developed to reduce the temperatures of their components exposed to sunlight and high temperatures.

Heat reflective paints were created with the aim of providing buildings with better thermal insulation: thanks to their special formulation, they reflect the sun’s radiation, preventing heat from penetrating into the walls. Surfaces coated with this type of paint do not absorb heat, remain cool, and consequently ensure that the interior temperatures do not rise, with significant energy and economic benefits.

Flooring coatings

Industrial flooring coatings are specially developed to be applied and protect surfaces exposed to heavy wear or corrosion. They are usually used on floors in warehouses, production facilities, car parks, ramps, stairs, walkways, and so on.

There are different types of flooring coatings on the market, from epoxy to ceramic and PVC. The choice depends on the requirements of the surface to be coated, including exposure to chemicals, wear, and abrasion, as well as other factors such as aesthetics, installation time, and coating service life.

Two different specifically formulated products were used to protect the flooring of the Louvre Abu Dhabi. The first one is a two-component polyurethane coating containing isocyanate for application on seamless concrete floors. It creates a waterproof membrane and provides high resistance to impact, abrasion, and weathering. The second one is a solvent-free coating developed for light/medium duty, which guarantees greater longevity, durability, and performance.

Super durable paints

Super durable coatings are premium paint products commonly used in architectural projects and designed to meet the most stringent specifications. They are formulated with a special type of polyester resin that provides enhanced protection against UV, weathering, salt, and moisture, as well as offering excellent abrasion resistance.

The wide range of colours, gloss degrees, and special effects available does not only bring functional benefits to structures, but also gives them high-quality finishes and aesthetics.

In an architectural project as important as the Louvre Abu Dhabi, super durable paints were a must. Specifically, a Qualicoat Class 2 powder coating conceived specifically for building façades and aluminium components was chosen, which can withstand the harshest weather conditions and provide protection against moisture and abrasion from sand and acid rain.

Antimicrobial paints

Antimicrobial paints are special coatings that are developed to protect both surfaces and humans. Formulated with special chemicals, antimicrobial paints hinder the growth and proliferation of pathogens such as bacteria, microbes, and microorganisms.

They are particularly suitable for high-traffic locations where there is statistically a higher probability of infection. Applying them to high contact surfaces (handles, buttons, switches, railings, etc.) helps to reduce the spread of possible infections or diseases to a large extent. Furthermore, they contribute to cleanliness by decreasing the presence of bacteria and germs in the air.

Based on these properties, a premium acrylic-based emulsion paint was chosen to protect the interiors of the Louvre Abu Dhabi, which has proven to be resistant to 22 varieties of bacteria and fungi.

Summing up

The Louvre Abu Dhabi was the first in a series of important cultural sites to be soon built. The ambitious project of the Emirates capital is to make the city of Abu Dhabi stand out in the international cultural scene. The construction of such a major architectural project took almost ten years and required over 5,000 workers. The coating phase was extremely crucial to protect the museum and its 55 buildings from the high temperatures typical of the Persian Gulf and the humidity resulting from the fact that the entire building is only 11 metres above sea level. As the museum is a highly frequented place, the project also included the application of antimicrobial paints.

Learn more about the types of paints mentioned in this article and stay up-to-date with the latest news from the surface treatment industry by subscribing to the free digital version of our technical magazines.