Today, 3D printed components made in the most diverse materials are increasingly widespread, thanks to the possibilities offered by this fast, inexpensive, and waste-free production technology conceived for prototyping or manufacturing parts with complex geometries. However, even these parts are subject to wear, corrosion, and harsh environmental conditions that can compromise their aesthetic and functional characteristics. Therefore, they must be protected with a surface coating. In this article, we analyse why and how plastic and metal 3D components are coated.

Additive Manufacturing, also known as AM, is a manufacturing technology that produces three-dimensional components based on computer models created with dedicated design software, through the superimposition of layers of a material, particularly plastic or metal – but today also paper, ceramics, and glass.

The last stage of their production process, i.e. the actual manufacturing of parts, is 3D printing. Widely used for the creation of prototypes before mass production or of specific products manufactured in limited and highly customisable batches, such as certain components in the biomedical, aerospace, naval, automotive, and even fashion and accessories sectors, this technology has found extensive application in various production fields. However, even AM parts are not immune to surface defects resulting from wear, corrosion, moisture, and harsh environmental conditions. This is why coating technologies are also becoming more widespread in this sector. Let us see how and why.

A bit of history

According to most sources, the first additive manufacturing system was created in the 1980s in the United States, thanks to huge military investment in advanced research after the end of the Cold War. According to other studies, however, the first experiment with material overlays dates back to the end of the 19

th

century, when J.E. Blanther patented a process of cutting and stacking wax sheets to create sets of moulds for pressing sheets of paper[1]. Regardless of its actual origins, we can however state that this production technology by “addition” of material rather than by “subtraction” (as in the much more widespread machining processes) has been widely developed into the most diverse 3D printing techniques since the 1980s. Here, we analyse the most common ones.

The most common 3D printing technologies / Plastics

The most popular AM technologies for 3D printing plastics are stereolithography, fused deposition modelling, and laser sintering. Let’s see them in detail.

Stereolithography or Stereolithography Apparatus (SLA): considered the oldest 3D printing method, it uses the principle of photopolymerisation to print 3D models with special light-sensitive resins that are cured with a UV source. Hardening is determined by the passage of the laser that creates the component layer by layer.

The post-processing phase involves several steps:

- Cleaning: isopropyl alcohol is generally used to remove excess resin from surfaces.

- Post-curing: the component is cured in a UV oven to complete the photopolymerisation that has taken place at the printing stage. This step is optional for standard resins, but necessary with some special resins to achieve optical, mechanical, and biocompatibility properties in compliance with current regulations.

- Smoothing: it is a process for smoothing edges and removing any imperfections or marks left by the support structures.

- Finishing: a finishing process, such as polishing with sandpaper or coating, is sometimes required. In some cases, a coating process by metallisation can be used.

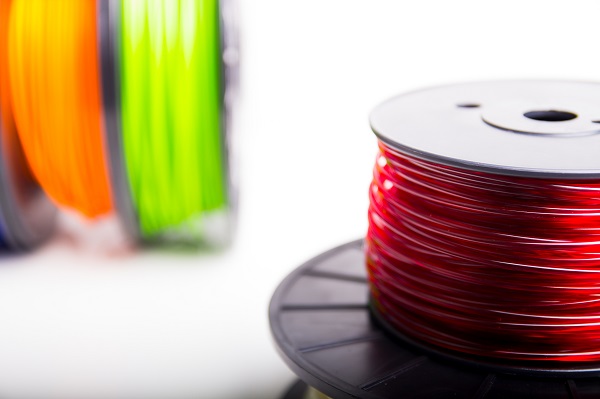

Fused Deposition Modelling (FDM) or Fused Filament Fabrication (FFF): it is considered one of the simplest 3D printing techniques and it consists of a plastic filament being pushed towards a heated moving head (usually at 200 °C), which melts, extrudes, and deposits it in the required shape, layer by layer. A moving platform gradually lowers to allow the subsequent layers to be deposited. During printing, supports are used to hold up the model, preventing it from collapsing.

© AdobeStock

© AdobeStock

A wide range of thermoplastic polymers can be used with this AM technology: the most common ones are PLA, ABS, Nylon, and PET. Materials such as TPU are generally the choice for 3D printing flexible parts. With the highest-performance printers, even engineering polymers such as PEEK and PEI can be employed, and water-soluble support materials such as PVA can be used. Some composite material filaments (consisting of a polymer matrix and filled with carbon or glass fibres) and metal-filled filaments, after being moulded as normal materials, require a sintering post-processing phase to evaporate the thermoplastic matrix and only leave the metal parts.

In most cases, components made with this additive manufacturing technology do not require any finishing. Since the materials (filaments) used are available in a wide range of colours, the parts are printed directly in the desired hue.

© AdobeStock

© AdobeStock

It is, however, possible to further finish the parts with a shot blasting operation.

Selective Laser Sintering (SLS) and Selective Laser Melting (SLM): it is the most popular printing method for industrial applications and it consists of sintering small polymer-based or composite powder particles into a solid structure by using a high-power laser. It is called Selective Laser Melting (SLM) in case metal powders are used (see next paragraph). After the realisation of a layer, the plate moves downwards so that the platform’s surface is covered again with material until the component is completed.

After printing, the post-processing steps are as follows:

- Cooling: after printing, the parts are completely covered by powder. The printing chamber must cool down to guarantee optimal mechanical properties and avoid deformation of the parts. Cooling can take up to 12 hours.

- Cleaning: after being removed from the printing chamber, the parts are cleaned with compressed air or another technique. The powder can be recycled and the printed parts are now ready for use or further post-processing.

- Post-processing: the actual post-processing phase consists of a surface finishing stage by shot blasting or polishing.

The materials used to print with this technique are thermoplastic polymers in powder form. The most used ones are polymers of the polyamide family (PA11, PA12, PA6), polystyrenes (PS), and thermoplastic elastomers (e.g. TPU, thermoplastic polyurethane). For special applications, composite powders made from a thermoplastic matrix and carbon or glass fibres, such as alumide, can be used to give the AM components dimensional stability and increased mechanical performance.

The most common 3D printing technologies / Metals

© AdobeStock

© AdobeStock

Powder Bed Fusion (PBF) and Directed Energy Deposition (DED) are among the most widely used AM processes for 3D printing metal components.

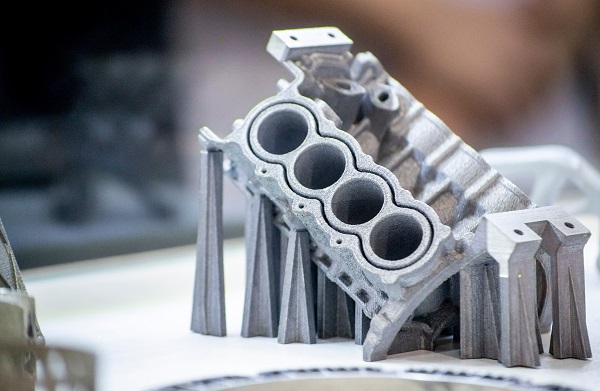

Powder Bed Fusion (PBF): this technology creates the components layer upon layer in a bed of polymer or metal powder. In the latter case, the powder particles are melted using a heat source such as a laser beam (Direct Metal Laser Sintering, DMLS, or Selective Laser Melting, SLM) or an electron beam.

DMLS or SLM: this process starts as always with the creation of a 3D model using dedicated software. For the actual printing step, the 3D printer fills the chamber with gas and heats it to a pre-set temperature. A thin layer of powder is applied on the plate with a pre-set thickness value. The fibre optic laser scans the cross section, melting the metal particles together. As each layer is completed, the plate moves downwards to allow a new layer of powder to be deposited. This operation is repeated until the part is completed.

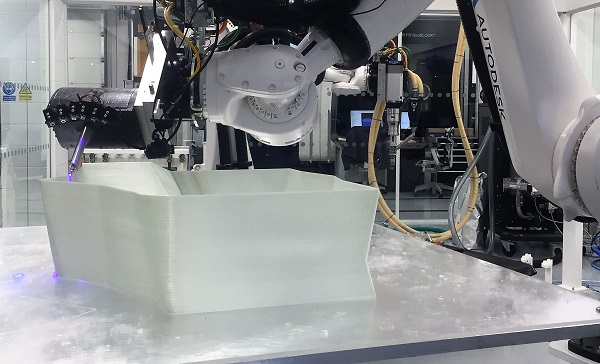

Directed Energy Deposition (DED): it uses a metal material in the form of powder or wire that is deposited or melted by a high energy density source such as a laser beam, electron beam, or electric arc. Laser beam-based DED systems require a completely inert chamber if working with reactive metals, or a local shielding with protective gas in the case of non-reactive metals. Wire-based DED systems are fed with a coil and the wire is pushed towards the nozzle through a mechanical handling system. Electron beam-based DED systems use only wire feed and the process must be performed under vacuum.

The most commonly used materials are aluminium, copper, titanium, nickel alloys, and stainless steel alloys. In particular, nickel alloys are widely utilised for their high tensile strength, friction and fracture resistance, and resistance to heat and corrosion. Steel is preferred for its mechanical properties and good surface finish. Titanium is a favourite for medical applications. High-cost precious metals are mainly used for the creation of complex jewellery.

© AdobeStock

© AdobeStock

The finishing of 3D prints

Smoothing

One of the hallmarks of additive processes is the less than ideal surface quality of the printed parts after the printing stage. This is why the advancement of AM technologies goes hand in hand with an increasingly pressing need to develop solutions for modifying 3D surfaces in the desired way during the post-production phase, making them more attractive and resistant through smoothing and polishing operations.

Smoothing, polishing, and shot blasting technologies – in many cases common to both plastic and metal-printed 3D components – include different processes: from surface homogenisation to polishing for both low roughness values and high gloss results. For these operations, it is essential to consider the AM technology employed, their surfaces’ grain size, the tolerances of the material layers applied, and the arrangement of the parts in the production chamber.

In the additive manufacturing of metal components, innovation is proceeding apace with the development of automated technological solutions that integrate proprietary hardware and software with chemicals that ensure that each moulded component has the required average roughness (Ra) and dimensional consistency while preserving all its details.

Another critical issue with metal 3D prints is the residual surface tension induced by the current additive technologies, which can lead to part deformation or poor mechanical strength. One of the solutions tested is the implementation of a shot peening process, which improves fatigue strength by delaying or eliminating the risk of cracks associated with stress corrosion, fretting, or pitting and reduces the negative effects of decarburisation and surface roughness even with delicate alloys such as aluminium. Finally, the moulded metal components tend to have very high yield strength values to the detriment of their elongation at fracture properties. This can be remedied using appropriate heat treatments, which differ depending on how and how much the metal’s internal microstructure is to be varied.

3D print smoothing is now common to all printing technologies and it is rapidly being automated with equipment and systems designed specifically to speed up operations. On the other hand, coating is still optional, both because, as mentioned above, some printing techniques already involve the use of pigmented material, such as FDM filaments for example, and because innovation in this field is opening up avenues yet to be explored. However, in this case too, apart from aesthetics, protective coatings should always be applied to ensure greater performance and durability.

Coating

Although the AM component coating process varies depending on the material and the application operation (manual or automated), traditional systems consisting of a primer, a base coat, and a final clear coat to protect the finished part are generally used. Layers can be applied in several coats and the workpieces can be polished in between coats to make the layer of paint as even as possible.

Other coating processes involve the use of PVD, CVD, or PACVD technologies. Let’s see them in detail.

- PVD (Physical Vapour Deposition): it deposits thin metal films on components made of different materials, in particular plastic and metal. The process takes place within vacuum chambers and it consists of the evaporation of the metals that make up the desired coating layer. These are transferred from the sources (targets) to the parts to be coated via steam or plasma, i.e. an ionised gas at low pressure. Deposition is aided by the presence of an electric field. In the case of the PVD sputtering technology, the process involves the emission of atoms, i.e. molecular fragments from the solid target material bombarded with a beam of energetic particles.

- CVD (Chemical Vapour Deposition): it is a synthesis technology that deposits a layer from a molecular precursor introduced in gaseous form, which then decomposes on the surface to be treated after being transported through the use of specific gases (e.g. nitrogen, hydrogen, and oxygen).

- PACVD (Plasma Assisted Chemical Vapour Deposition): it is a vacuum process used to deposit a diamond-like carbon (DLC) coating via plasma; this takes advantage of the chemical properties of carbon, namely the hardness typical of diamond and the flowability of graphite. The application of this coating ensures surfaces with higher wear resistance and different tribological characteristics[1].

Another technology for coating and protecting specifically metal AM parts is Plasma Electrolytic Oxidation (PEO), also known as Micro-Arc oxidation (MOA). This is an electrochemical oxidation process that produces hard, compact layers with exceptional properties in terms of abrasion resistance, hardness (about a quarter more than hard anodising), and corrosion resistance. The formed layer also has excellent temperature resistance and abrasion resistance.

Conclusions

Since its inception, the field of additive manufacturing has been constantly evolving, and the same can be said of its related coating processes, paving the way for numerous finishing solutions for 3D prints. For example, researchers at the South Ural State University in Chelyabinsk, on the eastern slopes of the Ural Mountains, have recently developed a metal-matrix heat-resistant coating. This new product provides heat, corrosion, and radiation resistance and it can absorb or reflect electromagnetic radiation.

© MOI Composites

© MOI Composites © MOI Composites

© MOI Composites © MOI Composites

© MOI CompositesFrom the smallest and most complex components up to a 6.5 m long boat that can actually sail, there is a feeling that additive manufacturing no longer has any limits in terms of production potential – or, if it does, that these can be solved and overcome quickly by developing ever more advanced technological solutions.