“L’arrivée d’un Train en Gare de La Ciotat” by the Lumière Brothers, one of the very first films screened in public in 1896, is a 45-second short showing the arrival of a train pulled by a steam locomotive at the railway station of the coastal town of La Ciotat, near Marseille, in France. Legend has it that some spectators in the auditorium, attending a film screening for the first time, ran away because they were frightened by the illusion of a moving train seemingly about to come out of the screen.

It was with these early experiments that the history of cinema began. But why did the Lumière Brothers choose a train as the subject of their first cinematographic endeavours? Because the train was, and still is today, synonymous with movement, speed, and... innovation. The construction of railway networks travelled by freight trains and passenger carriages in the first half of the 19th

century changed the economic and social face of the industrialised world of the time, speeding up connections and expanding geographical horizons.

Today, the country that holds the record for train travel in Europe is Switzerland. According to one of its latest press releases, Schweizerische Bundesbahnen AG (SBB), the public company controlled by the Federal Council that acts as the infrastructure manager and principal operator of this nation’s rail network, ended 2023 in the black for the first time since 2019, in the pre-Covid period, thanks to a new record number of travellers.

The rolling stock owned by SBB, which includes electric multiple units, freight wagons, and special-purpose infrastructure vehicles, reflects the diversity of an integrated railway company. “The train,” the statement reads, “is a climate- and land-friendly means of transport and will continue to play a central role in the global mobility of the future. At the same time, due to increasing demand, the capacity of railway nodes and the complexity of the system are reaching their limits. In order to meet these challenges, based on the RAIL 2050 perspective formulated by the Federal Council, SBB is developing a long-term strategy for its railways, which will ensure more flexible, frequent, and fast connections.”

To ensure such growth, however, the light and heavy maintenance of rolling stock calls for enhanced technologies and structures to guarantee the resistance of components against corrosion and wear and prolong their use as much as possible. Railway rolling stocks and their components are exposed to the atmospheric agents of the environment in which they operate, temperature changes, and humidity: therefore, if not adequately protected, they are subject to corrosion that can cause damage and, in the worst cases, even serious accidents. To avoid this risk, rolling stock must be protected with specific treatments enabling it to withstand corrosive stress throughout its entire nominal service life. Therefore, appropriate design and maintenance solutions must be chosen to achieve effective corrosion protection.

“Most of the work we do here, at the Bellinzona SBB workshops,” says Marco Siccardi, Project Manager of SBB (the German acronym by which the Swiss Federal Railways are identified), “relates to the heavy maintenance of railway vehicles. That means carriages and components must wait here for months for the maintenance activities to be completed as planned, in contrast to light maintenance, where partial intervention is possible each time a convoy reaches the station until completion.” When a train reaches the workshop, it is disassembled, and the wagons and other components are subjected to various repairs, including recoating. “One of our most recent investments was for a new liquid paint application and drying booth. Our company put out a public tender, which was won by Eurotherm Spa (Volpiano, Turin, Italy). This Italian company thus supplied us with a flexible plant with a totally innovative side extraction system.”

The Swiss Federal Railways’ fleet

In 2023, the rolling stock owned by SBB amounted to 691 electric trains, 219 shunting locomotives, and 172 self-propelled special-purpose infrastructure vehicles, totalling 1,916 passenger carriages and 4,518 freight wagons. “SBB has three train maintenance industrial hubs in Olten (one of the most important railway hubs in Switzerland, where mainly passenger trains are maintained), Yverdon-les-Bains (in the canton of Vaud), and here in Bellinzona, where maintenance work is carried out on passenger trains,” explains Siccardi. “Our rolling stock maintenance department is located underneath the railway station, from where convoys of a minimum of 7 and a maximum of 11 carriages travel directly to the underground floor along a track built especially for this purpose. We perform maintenance on all kinds of internal and external components.” After the total dismantling of the wagons, the required restoration work mainly related to corrosion issues and any modifications are carried out, followed by shot blasting, recoating with water-based paints, and drying, before final reassembly.

The future of the Bellinzona SBB workshops

“The Bellinzona SBB workshops,” Siccardi notes, “will be soon relocated from this long-standing site to a new area. After more than 135 years of activity in the heart of Bellinzona, the need has arisen to relocate the structure, which is no longer suited to meet the new requirements of the transport sector in the long term. After careful consideration, the choice of the new location fell on an area in the municipality of Arbedo-Castione, located a short distance from Bellinzona. That will free up a large area of around 120,000 m2, where around 500 people are currently employed, offering the chance to build a model district from scratch that will transform the surface currently occupied by the SBB workshops into a driver for the city’s urban development. At the same time, the new premises in Arbedo-Castione will allow a wide range of work to be carried out, with a focus on light and heavy maintenance of rolling stock, especially in the passenger train sector. With this project, SBB intends to build a new industrial hub that is socially, environmentally, and economically sustainable.”

SBB’s plan for new coating plants

SBB had put out a tender for installing new coating booths in Olten and Yverdon-les-Bains and building two coating plants on the new site in Arbedo-Castione. Siccardi confirms: “No new booth was intended to be acquired for the Bellinzona workshops because, with the site expected to be decommissioned, it would have made no sense to invest in a new system at the moment. However, since the beginning of 2023, we have been working on a renovation project for the Astoro fleet, a group of electric trains undergoing a wide-ranging renovation, upgrading, and recoating process whose completion is scheduled for 2027, and we needed to upgrade our paint shop to do this with excellent results. We had initially considered installing an inexpensive booth with essential features precisely because of the temporary nature of the plant, but we soon realised that we could not have achieved the required level of quality and, therefore, opted for a more professional system.”

The new Eurotherm booths were to be installed first in the workshops in Olten, then in Yverdon-les-Bains, and finally in the new plant in Arbedo-Castione. However, as Siccardi illustrates, “the workshops in Bellinzona urgently needed one, so we required it before the other maintenance sites: we started working with Eurotherm in October 2023, and on 1 May 2024, the booth was already installed at our premises.” That was also possible thanks to an innovative feature designed by this Italian plant engineering company: the booth’s side extraction system enabled to avoid excavations for the construction of a floor system, as is typical with this type of booth, thus speeding up delivery times.

The new coating booth

“The liquid paint application and drying booth we designed and installed at the Bellinzona industrial workshops,” states Eng. Davide Quartana, Project Manager at Eurotherm, “was conceived specifically for the railway sector and can accommodate both components and actual carriages.

The challenge the customer presented us with was twofold: it required a flexible solution to coat different types of rolling stock, and it wanted to avoid building work for its construction, since it is a booth for an existing plant.

Our technical team, therefore, customised the line by equipping it with a side extraction system partitioned into three distinct sectors: a series of extraction walls with a total length of 34 metres on both sides virtually divides the booth into three segments, each managed by an air handling unit (AHU) to guarantee recirculation over the three zones with the possibility of managing each zone independently. During coating, the operation of the extraction system is constrained by the operator platform’s positioning, which means that only two of the three available air handling units are active at the same time. Moreover, in addition to the 60 °C-drying function, the booth has a controlled temperature and humidity management system.”

The exterior of the coating booth with the side air treatment system designed and installed by Eurotherm. © ipcm

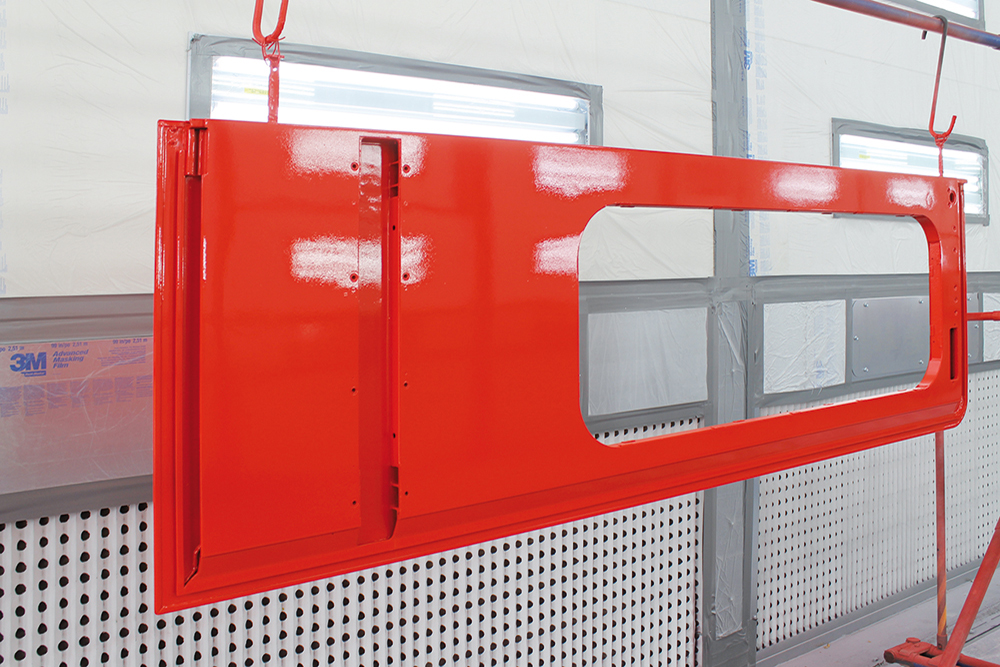

The exterior of the coating booth with the side air treatment system designed and installed by Eurotherm. © ipcm“After preparing each wagon for the coating stage by cleaning its surfaces and shot blasting them if required,” emphasises Quartana, “the customer applies three colours (white in two coats, blue, or red) and two lacquered layers. Thanks to the extraction system’s advanced 4.0 software, the operators can adjust different parameters to manage the temperature-controlled surface preparation and application phases. Air supply comes from the roof through a plenum space that is also accessible from the platforms to facilitate maintenance work. With this system, air is taken directly from outside the factory, poured into the plenum space via an extractor fan, and introduced by high pressure. The air thus enters the coating chamber and, after being filtered, heated or cooled, and humidified at constant values, it is always expelled outside, creating a cycle that is totally independent of the factory’s internal environment.”

A carriage ready for paint application. © Eurotherm

A carriage ready for paint application. © Eurotherm A stage in the application of the white primer. © Eurotherm

A stage in the application of the white primer. © EurothermEach of the three AHUs is equipped with an automatic water system to cool or heat the air according to the seasonal outdoor temperatures, so that the booth maintains a constant temperature range throughout the year. “The operator simply enters the parameters from the touch panel of the control PLC to automatically set the required temperature,” indicates Quartana. “The water chiller was designed and manufactured by Eurotherm, whereas hot water is supplied directly by the SBB workshops and distributed to the various batteries via servo-controlled valves.” Each of the three AHUs is also equipped with a system for controlling the humidity level through an osmosis water plant, which prepares the water to be atomised inside the unit, whereas humidity sensors are placed directly in the plenum space.

“Another interesting aspect of this air treatment plant is that, due to its enormous size, we had to resort to a helicopter to place its chimneys outside our building, a procedure that is quite common in a factory with oversized equipment such as the Bellinzona workshops.”

The advantages of the new solution

“In addition to the flexibility of the plant, which enables us to coat any type of rolling stock, from entire wagons to the smallest components, there are two aspects that we particularly appreciated in the design of this booth,” says Siccardi. “One, as already mentioned, is the innovative side extraction system that eliminated the need for excavations to install a floor system – which in an already existing factory is a complex operation and can lead to long production stoppages – thus reducing costs and simplifying maintenance, which can take place at the floor level. The other relates to energy savings: partitioning the booth into three zones with three independent AHUs means that only two out of three air handling units are activated at the same time, i.e. those in the area where operations are actually taking place, ensuring significant savings in terms of energy consumption.”

Innovation that breaks new ground

“Eurotherm’s team,” adds Quartana, “is going to inaugurate the construction site for the paint shop at the Olten site in October. It will include a shot blasting booth and two coating booths similar to the one installed in Bellinzona but with a floor extraction system. Finally, the Arbedo-Castione plant will have a shot blasting booth, booths for preparing the wagons and components, and two coating booths. The work carried out so far has been challenging due to the tight schedule, and we would not have been able to meet the deadlines and complete the job in the best possible way without the invaluable cooperation of the specialised train maintenance technicians of the Bellinzona workshops.”

“SBB is mobilising to purchase new rolling stock and renew its fleet,” says Siccardi. “The number of passengers and goods handled by our railway network is constantly increasing. For example, this is borne out by the fact that not long ago, we had to carry out major maintenance work on some old carriages that had to be put back on the tracks to cover the morning and evening rush hours at Zurich station.

Our work is essential not only to bring these worn-out vehicles back to life but also to ensure their excellent durability. That is why we must be put in a position to work with the best plant engineering and technological solutions, as was done here in Bellinzona. This project was an important turning point because SBB now knows it can take into consideration booths with similar characteristics to the one built here for future investments. This system’s performance is such that we will keep some parts of it in the new premises in Arbedo-Castione: we plan to move the booth’s external structure there and adapt the machine’s equipment to the new spaces, also to recover a part of our investment.”

Three colours can be applied on the wagons’ exteriors: white, blue, and red. © ipcm

Three colours can be applied on the wagons’ exteriors: white, blue, and red. © ipcm A door coated red. © ipcm

A door coated red. © ipcmMore and more people are choosing the train as a means of transport because it is considered more sustainable and convenient for covering long distances than cars or planes. That is why it is safe to predict that the number of travellers and the amount of goods transported by these vehicles is going to increase exponentially in the coming years – and, with them, the required rolling stock. Therefore, its maintenance, upgrading, and recoating will play an increasingly strategic and decisive role, making innovative solutions that can facilitate these interventions indispensable for the sector.