Belzona expands its Polymeric Portfolio with a new high performance structural epoxy adhesive: Belzona 7311.

Belzona has expanded its product portfolio by launching Belzona 7311, a cold bonding adhesive specially optimized for structural bonding applications subject to cyclic and repeated load where high mechanical strength, cleavage, shear and fatigue resistance are required. The combination of high-performance properties and ease of use makes Belzona 7311 a suitable solution for any engineer looking for bonding solutions.

Belzona cold bonding technology has already been used for decades for numerous application uses. Although these systems provide effective bonding solutions, they are designed to be used in a wide range of application areas and therefore are not optimized solely for use as structural adhesives. Given the clear demand for cold bonding solutions across a variety of application areas, the need for a polymeric solution that was exclusively designed for structural bonding applications emerged.

“Thanks to our historic success with Belzona systems in thousands of bonding applications over the years, we had access to a wealth of knowledge and experience when formulating our brand-new structural adhesive. Building on this knowledge, we were able to really push the boundaries of what can be achieved with Belzona cold bonding technology. The result: a high-performance product that is perfectly formulated to meet the exact structural bonding requirements found across a wide variety of application and industry areas”, said Jason Horn, one of the main developers behind Belzona 7311, Research and Development (R&D) Manager.

The advantages of this Belzona's new technology are:

- High resistance to cyclic fatigue and peel/cleavage forces.

- Excellent adhesion to metallic substrates.

- Suitable for dry or wet service between -30 °C (-22 °F) and 60 °C (140 °F).

- Cold-curing, solvent free material keeps application environment safe.

- Easy to mix and apply without specialist tools.

Belzona 7311 is an alternative to welding and mechanical fastenings/fixings

Welding is a common bonding method used throughout many industries. However it is not without limitations: the welding procedure transmits the applied loads throughout the weld seams only, requires hot work permits and specialized equipment, it is not optimal for dissimilar metals, and it can often be difficult to install with complex shapes or where accessibility is poor. Furthermore, the heat generated by welding can result in heat affected zones and stressing of the welds unless heat treated, which can lead to increased corrosion. Also mechanical fastenings or fixings are popular jointing/assembly solutions, but sometimes they can prove to be problematic.

Belzona 7311 successfully bypasses these problems in the following ways:

- Adhesive applied to cover the entire joint, resulting in uniform stress distribution and load transmission, reducing metal distortion under strain

- Good damping properties give high toughness and fatigue resistance

- Can accommodate complex shapes and be installed where accessibility is poor

- Minimal training required for application procedure

- No hot work or specialist equipment required

- Does not promote corrosion

- Lightweight and easy to apply, reducing costs and labour

Comprehensive performance data enables maintenance teams to perform finite element analysis (FEA)

Having produced an extensive portfolio of mechanical and performance data from development and testing of Belzona 7311, reliability and maintenance engineers can use this information to conduct FEA to design bonded joints and assemblies.

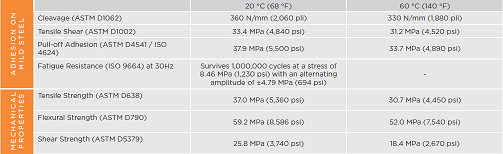

Table showing some of the available adhesive strength and mechanical property data for Belzona 7311

Table showing some of the available adhesive strength and mechanical property data for Belzona 7311With this information, personnel can evaluate the Belzona 7311's performance against the real-world forces it will be subjected to during use. This helps provide demonstrable evidence that epoxy technology will deliver the required performance levels within the designated application environment.

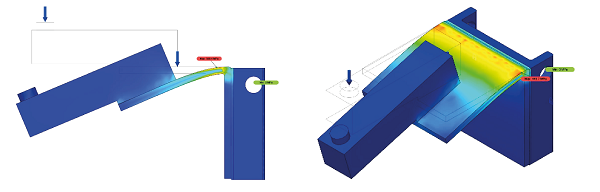

Performance data used to perform finite element analysis (FEA) of a bonded bracket

Performance data used to perform finite element analysis (FEA) of a bonded bracketBelzona 7311 application

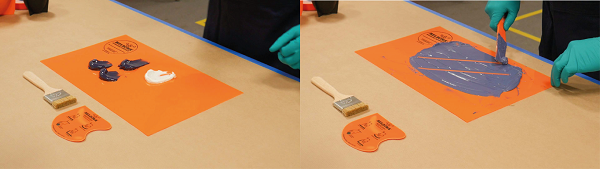

2-part epoxy adhesive easy to mix and apply

2-part epoxy adhesive easy to mix and applyThe substrate is prepared by grit blasting to ensure a surface profile of 75 µm (3 mil) and cleaned according to ISO 8501-1 Sa 2½. Subsequently, the required amounts of base and solidifier are mixed together in a 3:1 ratio until a uniform, streak-free material is obtained. The system is then ready to be applied to the application area using a short-bristled brush and a Belzona applicator.

Base and solidifier mixed together to achieve a uniform material, free of any streakiness

Base and solidifier mixed together to achieve a uniform material, free of any streakinessOnce applied, the system is then left to cure. To achieve maximum adhesive strength, the cure time can be as little as 48 hours when the temperature is 20 ° C (68 ° F) and can be accelerated depending on the ambient temperature.

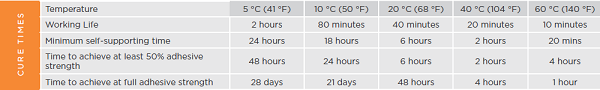

This table provides more information on the cure times required for different temperatures

This table provides more information on the cure times required for different temperaturesA solution for asset owners

Compared to conventional epoxy adhesives, Belzona 7311 has been toughened to offer a combination of high mechanical adhesion strength and cleavage, shear, and fatigue resistance. Maintenance personnel and reliability engineers can now specify a Belzona structural adhesive which can be FEA-modeled and engineered to deliver a state-of-the-art solution to assets subject to cleavage, shear, and repeated loads.

In turn, this helps to keep facilities’ operations running as smoothly and efficiently as possible, as greater adhesive strength decreases the bonded area’s susceptibility to failure. Thus, investing in Belzona 7311 helps asset owners to mitigate the costs that can be incurred to not only repair or replace damaged assets, but also in terms of the lengthy periods of downtime that can ensue should a bonded area fail.

Belzona 7311: a high-performance epoxy cold bonding solution

Belzona 7311: a high-performance epoxy cold bonding solution