The modular EcoProWet PT chemical pretreatment system developed by Dürr offers savings on space, energy and materials.

The German engineering company Dürr has recently presented EcoProWet PT, a new flexible and scalable chemical pretreatment system specifically developed for compact and modular automotive coating lines. In coating plants for automotive and other vehicles, the pretreatment phase is still one of the process steps requiring the most space, since the tanks are usually designed for big body dimensions and long process times. Besides requiring less space and construction times, the new concept – which is particularly suitable for small to medium production capacities – ensures substantial savings on energy and materials.

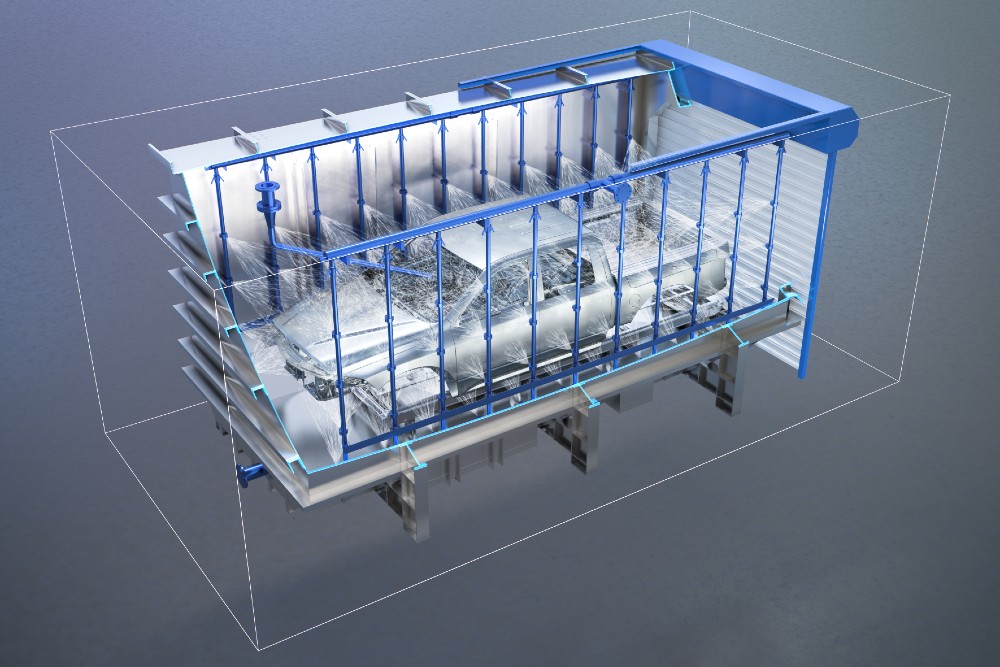

Instead of using large tanks, the innovative EcoProWet PT pretreatment system from Dürr envisages compact chambers which are flooded or designed as spray chambers depending on the process step: the car body is loaded through a roller shutter door into the tunnel and led to the respective process chambers.

In the spray chamber, the parts are treated using a large number of nozzles that can be directed to different angles, in order to reach critical areas such as door sills, as well as flexibly switched on and off according to the size and shape of the car bodies. Furthermore, a lance with a special rotating nozzle also ensures the targeted and efficient cleaning of the interior of the components. In the flooding chamber, on the other hand, the pretreatment product is fed into from a buffer tank located above, with the resulting momentum further helping to clean the body. The filtration process to recycle the cleaning liquid takes place in the full volume flow on the way back from the counter tank to the buffer tank.

The spray chamber of the EcoProWet PT pretreatment system of Dürr.

The spray chamber of the EcoProWet PT pretreatment system of Dürr.Like the chambers themselves, all the other elements (the tunnel, the steel structure, the conveyor technology and the door that securely seals the flooding chamber) of the system have a modular design that does not only ensure efficient logistics, but also short assembly and commissioning times during construction. Moreover, the concept can withstand the water pressure even during flooding or when the chamber is completely full and the optional insulation of the door contributes to the energy efficiency by reducing the amount of heat loss.

In series operation, the cycle times and system modules are coordinated with each other in such a way that the buffer tank is filled whenever fluid is needed. Since the pumps are likewise controlled in accordance with the actual need, the energy required can be reduced to a minimum.

Finally, the EcoProWet PT chemical pretreatment system developed by Dürr is suitable for thin-film processes, since it has been created in close cooperation with the international chemical manufacturers BASF/Chemetall

and Henkel. The company has also already carried out extensive test series to validate the new concept in a purpose-built pilot plant.