The ongoing digitalization and networking of manufacturing processes is changing the face of production. Part cleaning is no exception to this trend. Ecoclean's innovative cloud solution CareConnect for the digitalization of cleaning systems enables users to optimize process reliability, equipment availability, production planning and overall equipment efficiency, thereby helping to enhance productivity and hence, competitiveness.

The 4th industrial revolution is well under way. It is marked by the increasing digitalization and interconnection of machinery and equipment components, as well as of products, value-adding chains and business models. The aim is to

optimize industrial operating effectiveness, enhance competitive conditions, generate further growth, and thereby safeguard companies' future viability.

This trend brings new challenges, including in industrial parts cleaning. One of them is to ensure that the data obtained by the permanent, state-of-the art capture, monitoring and documentation of diverse equipment parameters such as, e.g., pressures, temperatures, power consumption and operating hours, can be intelligently used. To this end, Ecoclean has developed the CareConnect cloud solution, which permits an integration of several cleaning systems for an effective equipment pool management.

Comprehensive information on machines and processes

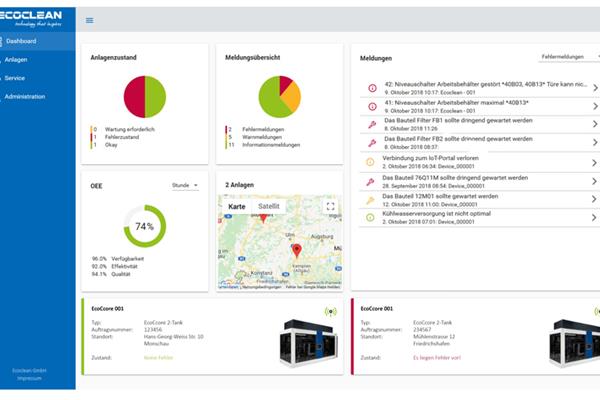

Defined data generated by the machine control system are transmitted to the cloud via a secure link. There, they are stored, analysed and intelligently interconnected. For visualization, the information is presented in dashboard

form on a desktop computer or tablet.

For the equipment user this innovative cloud-based solution adds value at various levels. Thus, data on the cleaning process as well as the associated machine operating information – including a full data history – can be retrieved

at any time, ensuring documentation continuity. In the event of a malfunction, a diagnosis can be derived quickly and easily from this information without any need for laborious troubleshooting. Moreover, the cloud solution permits the

calculation of so-called key performance indicators (KPI). Overall Equipment Effectiveness (OEE), for instance, is a measure characterizing a plant's availability rate and operating effectiveness. Based on these metrics, the user can determine whether the system is capable of handling a projected higher cleaning output. This may be helpful in optimizing the utilization of production equipment and processes. The cloud also holds information on parameters

such as the distillation??? rate, which in turn can be used to judge the quality of media reconditioning. Consumption figures are a measure, e.g., of whether the system's electrical power demand lies within normal limits. Any deviation

here may point, e.g., to a component failure. In the event of a fault it is possible, furthermore, to send malfunction reports directly from the equipment via the cloud, thereby reducing communication barriers. Unscheduled machine

downtimes can be prevented via the maintenance forecast, which can tell the user at any time how many batches remain to be cleaned or how many operating hours are still available before the next maintenance is due. In

addition, CareConnect can provide a continuous documentation of equipment and process conditions for any given batch or discrete component, consistent with present-day requirements in the aerospace, medical equipment,

automotive and other industries.

High level of security and transparency

The data transfer from the PLC to the cloud takes place via an interface meeting state-of-the-art data and communication security standards; moreover, it can be easily integrated into existing IT systems. The user has full

transparency regarding which data was captured for which purpose. A further level of safety was implemented by ensuring that all access to the PLC is read-only. Thus, any external interference is practically ruled out.

These benefits, in addition with the added value delivered by the cloud solution, help to increase the process reliability and productivity of cleaning equipment. The digitalization solution was realized initially for the EcoCcore

solvent-based cleaning system but will be continuously expanded for further machine types.