The measuring instruments from Krüss will use a new dosing system to quickly measure the retraction behaviour of dosed drops.

Many industrially relevant surface properties – such as coatability, cleanliness and adhesiveness – are directly or indirectly linked to wettability, which is therefore often tested as part of quality assurance controls. In contrast, dewetting (i.e. the contraction and possible run-off of the liquid from the material) has rarely been investigated, even though its behaviour is particularly informative for many materials, such as hydrophobic and self-cleaning surfaces.

Moreover, dewettability also reacts sensitively to material pre-treatment and it is therefore an ideal test criterion. The result relevant for dewetting is the so-called receding angle, a variant of the contact angle. The measuring instrument manufacturer Krüss has now developed the Stood-up Drop for the optical measurement of the receding angle.

As a matter of fact, the Hamburg-based (Germany) company Krüss has recently announced that its contact angle measuring instruments will use a new dosing system to measure the retraction behaviour of dosed drops in a matter of seconds. The new method developed by the international provider of measuring instruments for surface and interfacial tension complements conventional contact angle methods and expands the application possibilities of wetting measurement for testing material surfaces.

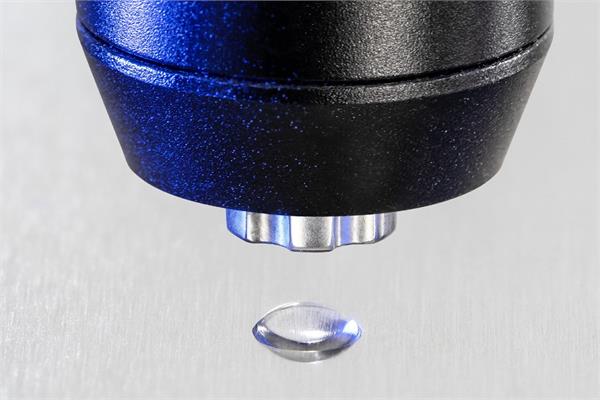

The new dosing unit for the Stood-up Drop method places a drop of water on the sample with high and controlled dynamics. The liquid initially spreads out flat and then contracts at lightning speed to form a defined drop. A camera then captures the drop in a video image, which is analysed to determine the receding contact angle within seconds.

The potential of the new Stood-up Drop dewetting method

Measuring the receding angle has the potential to supplement or even replace other test methods for surfaces: in extensive preliminary investigations, the results have shown good correlations with pre-treatment parameters, such as for corona, plasma and flame treatments – but also with the results of common test methods.

For example, pre-screening with the receding angle has already reduced the amount of elaborate material testing in applications like the measurements of the Moisture Vapor Transmission Rate (MVTR), employed to quantify moisture protection and breathability.

Since the measuring sequence and the dosing parameters are predefined, the results are user-independent. Furthermore, thanks to the speed of the new approach, the receding angle can now be used for quality tests even with large numbers of samples. Finally, as it does not use any harmful substances, it is also safer than using test inks whose areas of application overlap with those of the Stood-up Drop.

Krüss is offering a free three-part webinar on the new Stood-up Drop method, in order to provide more in-depth information on the wide range of possible applications.