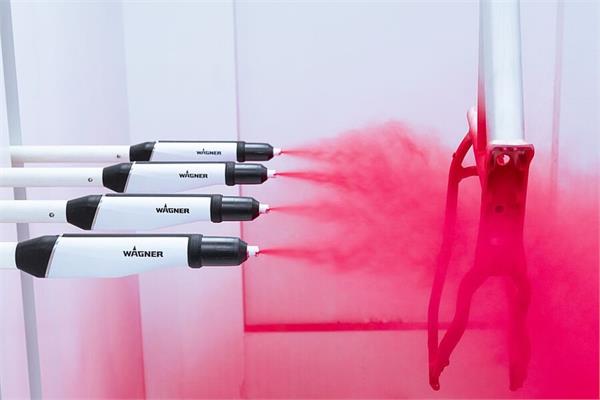

The new automatic guns from Wagner provide high powder coating results with maximum application efficiency.

The Wagner Group has introduced a new range of automatic spray guns for powder coating that combine high performances with maximum application efficiency in coating systems (PEA-X1) as well as robot-based production environments (PER-X1). Their modular design and the variety of their accessories enable a wide field of applications for all requirements.

The spray guns also improve the flexibility of the powder coating process. For example, the basic gun of the PEA-X1 can be combined with a bracket, XL extension or robot adapters. The PER-X1, in turn, can be combined with various robot mounts for single or dual use. Furthermore, there are also various nozzles that are compatible with the PEM-X1 manual gun – part of the product family. The new angled nozzles, for example, can be used to reach difficult spots on the workpiece, while the angled adapter expands this feature even further.

They are suitable for both single-colour and colour change systems. The optimised and streamlined design of the CoronaStar provides minimal areas for powder accumulations

on the gun body and ensures the efficient automatic blow-off during colour changes. So, the guns provide a more stable production process without waste.

The improved powder cloud results in thinner and more uniform coating thicknesses. As a result, powder consumption is also significantly lower. In addition, powder accumulations in the nozzle or spitting occurs less frequently thanks to the improved internal geometry.

Already installed systems with the previous automatic guns can easily be retrofitted with the new ones. The installation and maintenance are very simple, thus reducing service costs.