In the exclusive world of cosmetic packaging, product wrapping is not simply a matter of containers but a crucial element of branding, capable of communicating emotions and conveying an image of quality and sophistication. Sometimes, outer appearance can even outweigh the importance of the content itself. The quality of the wrapping inevitably depends on the perfection of its coating. The Decorluxe Group stands as a centre of excellence in luxury packaging in Italy – an achievement reached thanks to the extraordinary and far-sighted vision of Claudio Mottini, the CEO of V.M.C. Mottini, and the solid collaboration of trusted, long-standing partners, including liquid paint manufacturer Vernici Caldart.

Have you ever walked through the aisles of a supermarket or shop and found yourself attracted by a product on the shelf, driven by curiosity about the shape, size, or colour of its packaging? That moment of spontaneous attention is never accidental.

In perfumery and cosmetics, packaging is no longer just a wrapper enclosing a product. It has become an actual “emotional extension” of the brand, a means to tell its story, amplify its values, and create deep connections with the consumer. In this context, the coating applied – the very soul of the packaging – becomes the distinctive element capable of making the difference between a simple package and a complete sensory experience.

“‘The essence you possess, clothed by us’ is one of the claims that best sums up our work,” explains Cristina Palara, Export Developer Manager at the Decorluxe Group, the Italian hub specialising in luxury packaging for the perfumery, cosmetics, skincare, make-up, and beverage sectors. “Visual appearance comes before smell, taste, and touch, and we aim to draw attention by giving each package a unique personality through eye-catching coatings that will strike a chord in both our customers and their end consumers when they notice a product stand out among all the other on the shelf.”

Nowadays, however, packaging is not just about aesthetics but also strategy. Not infrequently, the container is perceived as even more important than the content itself, thus becoming a crucial communication tool for brand positioning. At the same time, as the importance of wrapping quality grows, significant questions emerge about its production and use. “The cosmetics industry is going through a period of profound transformation driven by a growing awareness of its environmental and social impact,” Palara emphasises. That is no longer limited to raising awareness about the use of natural ingredients or resource consumption but encompasses the entire life cycle of products, from raw materials to formulation, from packaging to end-of-life.

“To drive genuinely sustainable developments, we need an approach to eco-design based on precise parameters. These range from choosing materials with the best environmental performance to reducing packaging weight, from reuse and refill solutions to design simplification and, last but not least, finishing. Implementing production cycles with a reduced environmental impact is decisive for companies wishing to remain responsible and, at the same time, competitive. In this sense, a paint supplier’s contribution is strategic: since its foundation in 1997, V.M.C. Mottini, the company from which our Group originated, has chosen Vernici Caldart (Bellusco, Monza e Brianza, Italy), a provider specialising for almost fifty years in the formulation, production, and sale of liquid paints for plastic and glass for the packaging, eyewear, industrial, and refinish sectors.”

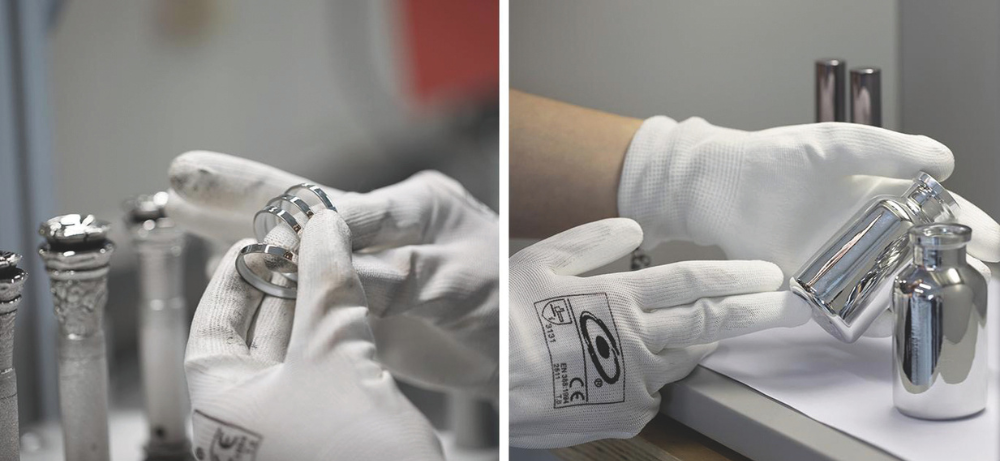

The 7 coating lines apply a wide range of hypoallergenic, non-toxic, water-based coatings. © Decorluxe

The 7 coating lines apply a wide range of hypoallergenic, non-toxic, water-based coatings. © DecorluxeA futuristic cosmetics hub project: when unity is strength

The idea from which Decorluxe, Italy’s cosmetic packaging hub, originated two years ago was the result of the foresight of Claudio Mottini, the CEO of the Group’s parent company, V.M.C. Mottini (Chiuduno, Bergamo, Italy). Since its foundation, it has focussed on the coating of products for the fashion and cosmetics industries, quickly establishing itself in a niche of excellence – that of cosmetic packaging – thanks to the use of different technologies, including coating, screen printing, pad printing, hot stamping, UV sputtering, and sublimation.

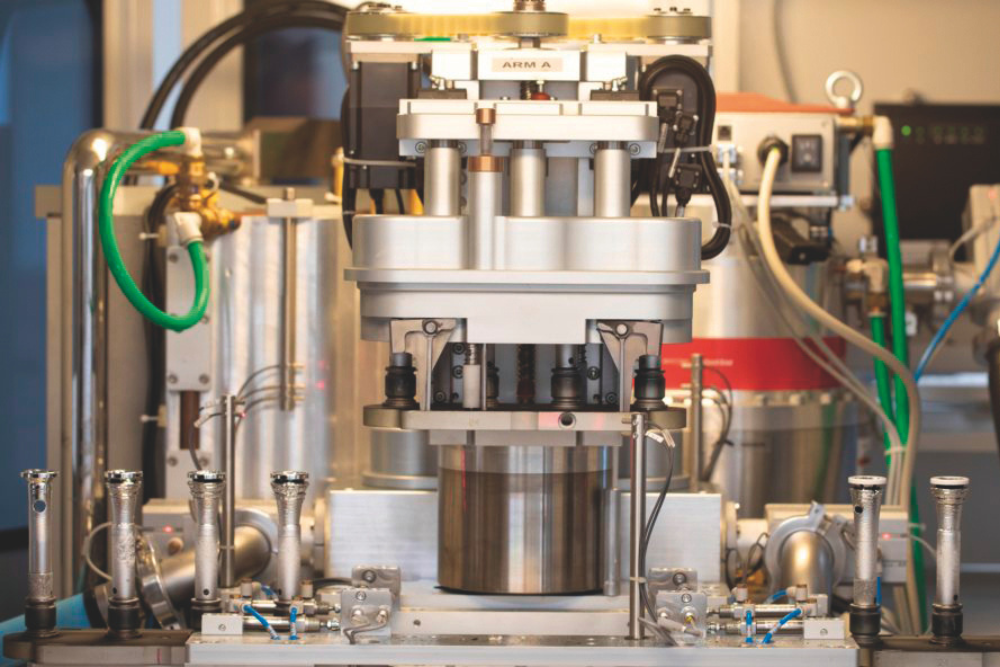

One of the Group’s latest investments was a new PVD sputtering plant for metallising mascara packages. © Decorluxe

One of the Group’s latest investments was a new PVD sputtering plant for metallising mascara packages. © Decorluxe

“We are unique in Italy,” states Palara, “because nothing like this had ever been conceived within our borders before. In Claudio Mottini’s vision, the creation of a Group consisting of formerly competing companies with consolidated experience in their respective fields of specialisation would guarantee immediate operability without ramp-up periods, which could compromise the fulfilment of orders. Its project is based on the objective of providing customers with a single point of reference able to receive the raw products and return them ready for filling. The innovative aspect is precisely the Group’s ability to offer a full service so that, from the moment the container is received to its delivery, our customer no longer has to worry about anything.

This strategy was also endorsed by Ethica Global Investments, a holding company that invests in Italian SMEs, which enabled the Decorluxe Group to bring together the best expertise in the sector of surface finishes for luxury packaging. In addition to V.M.C. Mottini, the Group includes Verbar, a benchmark supplier in the glass, metal, and plastic coating and 3D glass sublimation market for perfumery, cosmetics, and wine & spirits luxury packaging; Plast.Met, which for over fifty years has been offering vacuum metallisation and coating services on plastics and glass for the cosmetics and wine & spirits industries; Aurora, active in the decoration sector through hot stamping, screen printing, pad printing, and digital printing; Eurovercos, which develops traditional and UV surface treatments with liquid application of organic colours and specialises in the customisation of glass, plastic, and metal surfaces for the furnishing & furnishing accessories, perfumery, and cosmetics sectors; and Décor-Style, which specialises in the mirror-effect hot engraving of logos, lettering, and bands on plastic and aluminium products for the most prestigious national and international brands, also including the hot transfer process.

“Instead of competing, these companies can bring their processes full circle, doubling their equipment and offer through staff already trained and made up of true professionals in each sector, thus providing their customers with an all-round service that also includes handling, reduces times, and ensures greater control over the quality of finished products. The Group boasts an impressive equipment fleet of 109 production lines, including 7 coating lines, 15 glass decoration systems, 1 sublimation machine, 15 pad printing plants, 60 machines for hot stamping and foil heat transfer on plastic, 7 screen printing lines, 1 metallising plant, and 3 UV sputtering systems; one of these is an innovative automatic line we installed in 2018 to complete the range of processes in V.M.C. Mottini’s portfolio. As a Group, we currently produce more than 2,000,000 workpieces daily.”

In search for the perfect tailor-made “dress”

In such a competitive environment as luxury packaging, the demands for customisation have reached very high levels.

“The processes are becoming increasingly complex, and the creativity of designers sometimes reaches such a point that it is the very company that commissions the product that realises it has gone overboard and takes a step backwards,” Palara says to describe the current trends in this industry.

“The technological aspect of machining processes and, consequently, of the products used to carry them out has become more efficient than ever before,” notes Christian Sala, Italy Sales Director at Vernici Caldart. “This sector, more than others, presents product innovations at an astonishing rate, almost daily, because it borrows the trends of the fashion world, whose marketing is conditioned by the need to continuously launch new products. That is why, as paint manufacturers, we must keep a close eye on the demands that companies like Decorluxe place on us, even the most complicated and challenging ones.”

Gianluca Zanardo, Vernici Caldart’s Export Sales Director, explains: “For some projects, we can achieve the required results with the products that our laboratory has already developed, but in other cases, it is necessary to develop new, made-to-measure ones from scratch. In these cases, the collaboration with our customers must necessarily become closer. We also offer an after-sales assistance service to respond promptly to any requests and problems that may arise.”

“We at Decorluxe like to think that our collaboration with Vernici Caldart is human as well as technical, a cooperation between people who share the same goals, a synergy between two companies that interface with each other to create a relationship of mutual trust and growth in which chemistry is the basis and a green approach its driving force,” Palara points out.

The Group works with the most important international players in the industry. “It is understandable, therefore, that the specifications submitted to us require compliance with the highest standards of quality and sustainability,” Cristina Palara reiterates. “Quality control is a crucial phase of our workflow, and we carry it out with leakage and product conformity tests, including the most rigorous and advanced ones available on the market, in compliance with regulations and using the same measuring and control tools as our customers, to guarantee uniformity of results. Previously, we entrusted some external bodies with the analyses for product certification. Now, Decorluxe is equipped with a lightbox to visually assess and compare colours under three different light conditions (office light, daylight, and combined light), an ageing oven for tests at a constant temperature for 24 hours, a climatic chamber, sun test and abrasion test instruments, a sclerometer and military standard tools, and a statistical control system for finished products.”

Vernici Caldart’s high-performance chemicals

As Cristina Palara emphasised several times during our interview, the most radical changes the industry is undergoing concern sustainability. Packaging is becoming an increasingly important aspect of a product’s ecological footprint.

Vernici Caldart supplies Decorluxe with two types of coatings: water-based coatings for glass products intended for the perfumery, cosmetics, and beverage sectors and UV coatings for the PVD treatment of plastic and glass container components. “Decorluxe has already made a fundamental step forward by replacing solvent-based paints with water-based ones and introducing PVD coating technology to replace the less sustainable galvanic coating process,” indicates Vernici Caldart’s R&D Manager Paolo Marchesi. “I personally supervised the project for the latter transition at Plast.Met: vacuum metallising enabled the company to reduce emissions by 80% while achieving higher coating results. Our laboratory developed a special, water-based pre- and post-metallising coating that met specific high temperature resistance, gloss, adhesion, and bottling resistance characteristics.”

One of the Group’s latest investments was a new PVD sputtering plant for metallising mascara packages. © Decorluxe

One of the Group’s latest investments was a new PVD sputtering plant for metallising mascara packages. © Decorluxe

“Today, fewer and fewer customers request polluting processes such as electroplating,” Palara confirms, “but more and more of them ask for green certification of our processes, especially abroad. In the European Union, relevant regulations heavily affect the technological evolution of the glass and plastic decoration sector. For this reason, we have not only planned to get all the companies in the Group certified to ISO 9001 (except for V.M.C. Mottini and Aurora, which are already so) but also to obtain Ecocert certification, which verifies the conformity of products to specific ecological and social standards, in the shortest possible time.”

Being a driver of sustainability

The Italian cosmetics market in 2025 is expected to register an 8% increase in turnover, with exports increasing by 10%. Italy plays a crucial role in the global cosmetics industry, primarily through contracting, which generates a turnover of around EUR 2 billion (2023 data) with strong annual growth and a significant part of production destined for international markets. “Italian companies in the cosmetics cluster are recognised for their excellence in product formulation, production, and packaging,” Palara concludes. “Being part of this world is, on the one hand, exciting, and on the other, extremely challenging, especially for companies that, like Decorluxe, have chosen to interface with a niche market, that of luxury packaging. We are proud to have become a benchmark manufacturer through the sustainability practices we have initiated in close collaboration with Vernici Caldart, without which we could not have achieved this important result. However, there is still a long way to go to bring the entire cosmetics sector to a degree of environmental sustainability that meets expectations. As we have already pointed out, product innovations, combined with the creativity of packaging designers, know no limits, and we must be ready for anything. Because the first impression is the one that counts, and a valuable product must have a ‘dress’ worthy of its value... along with, now more than ever, environmental footprint certification.”