Dürr Megtec recently released the next generation of its wet electrostatic precipitator (WESP), an air pollution control system that efficiently cleans industrial gases of fine particulate matter, acid mists and aerosols to meet global environmental regulations and protect downstream equipment.

Dürr Megtec, part of the Clean Technology Systems division of the Dürr Group, designed the new WESP placing a strong focus on the system’s high-intensity, offline automatic cleaning features, which reduce maintenance efforts, eliminate carryover of entrained matter during washing and provide better operational performance during cleaning. System components are also now easily accessible for maintenance inspections.

“After talking to our customers, our product development departments generated innovative, patent pending ideas in the area of particulate removal efficiency, and tube and electrode cleaning – all with a keen eye towards reduced maintenance and increased reliability,” says Dr. Daniel Schmitt, President & CEO of Dürr’s Clean Technology Systems division.

WESP air pollution control systems are used in all sectors of industry, including wood, waste incineration, food processing, biofuels, metals and mining, chemical, petrochemical, iron and steel, and pulp and paper. Dürr WESPs can remove up to 98% of particulate in a single stage, depending on the characteristics of the gas stream. Increased removal efficiency is possible with alternative configurations.

Enhanced performance

In order to enhance the performance by achieving a more efficient contaminant capture, Dürr increased operating voltage that requires less collecting surface area. Additionally, the gas distribution system was completely reimagined to optimize flow through the system, and various tube shapes and electrodes were tested to improve overall performance.

Reduced fabrication and faster installation

In order to reduce engineering time and streamlining fabrication, the new WESP systems are assembled from different standard modules and adapted to customer-specific requirements.

Modules with tube bundles are pre-assembled in the production facility for shipment to the customer and all electrodes are pre-loaded and pre-aligned, thus ensuring faster installation times.

A pilot program to establish proof of concept

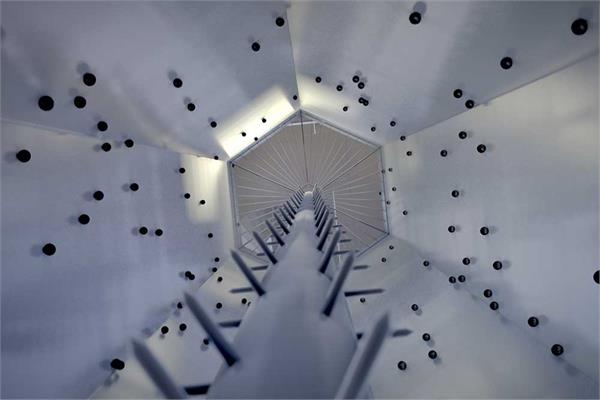

Numerous scale models were used to establish proof of concept before ideas were implemented. Based on that work, extensive field-testing was done under real-life conditions with large, to-scale equipment. Results of the pilot program were used to prove final concepts and performance prior to commercial scale production.

“The next generation design addressed industry-specific feedback obtained from users and operators,” adds Dr. Schmitt. “We are excited to get this equipment to the market, so that both our customers and the environment can benefit.”