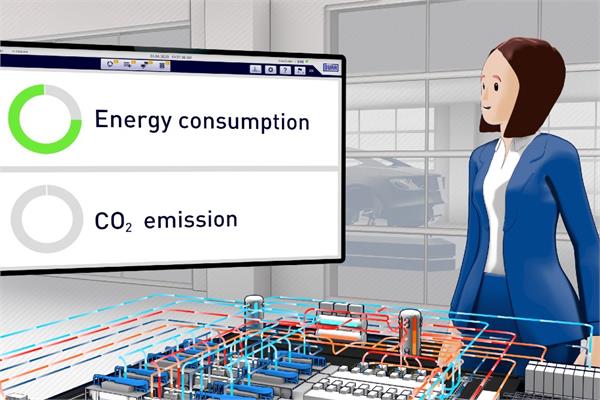

The energy recovery concept EcoQPower allows Dürr to build EU Taxonomy-compliant paint shops.

Dürr

has recently announced that the Fraunhofer Institute for Building Physics (IBP) has carried out an independent and comprehensive life cycle assessment of its EcoQPower system, certifying that the paint shops employing the concept can reduce CO2 emissions by 19.2% over their entire life cycle compared to paint shops without the system, mainly due to an energy consumption reduction of around 21% in the utilisation phase – making it the first solution to comply with EU Taxonomy requirements.

In fact, paint shops consume the most energy throughout the entire vehicle manufacturing process, because applying paints and drying car bodies are very energy-intensive steps. The new concept analyses energy sources and energy sinks in operations, considering various operating states and historic climate data. Based on this assessment, the EcoQPower energy network systematically recovers energy in one place, which can then be reused elsewhere.

“The EU wants to be climate neutral by 2050. We had this target in mind when we adopted a new strategy on the path to a carbon-neutral paint shop from an energy perspective. Instead of continuously increasing the energy efficiency of individual elements such as paint booths and ovens, as we did before, we developed the EcoQPower system, which considers all paint shop energy sources and network components, as well as energy flows,” has declared Jens Oliver Reiner, the senior vice-president for the sales in the Paint and Final Assembly division of Dürr.

The EcoQPower concept from Dürr

The EcoQPower concept developed by Dürr is based on the idea that each manufacturing step should only receive the appropriate energy and temperature level it actually needs.

So, the various technologies that constitute a painting and coating system, such as the pre-treatment tunnel, the oven and the application booth, are not considered and supplied as individual components.

By considering the entire scope, the EcoQPower system integrates all waste heat sources – including those not previously used – and reuses energy at low temperatures, with the heat pumps that generate heating and cooling energy simultaneously. The experts from the company also measure the heating and cooling requirements of each paint shop process step, leveraging synergies from the processes and – in combination with resource-saving technology – enabling economical energy use.

The EU Taxonomy

The EU Taxonomy is an instrument developed under the Green Deal to make Europe the first climate-neutral continent by 2050. By providing a transparent classification of sustainable investments, the regulation aims to ensure that financial resources fund projects that support climate and environmental protection.

“Sustainability is becoming increasingly important for companies in the manufacturing sector. We help our customers make their production processes as energy-efficient as possible to achieve their decarbonisation targets. We know that companies engaged in sustainable production will have more and more advantages in the long term for sourcing funding in Europe,” has concluded Reiner.