The UltraPLAS coating by Fraunhofer is an ultrathin, highly durable layer with excellent non-stick properties that significantly reduce the need for external release agents and post-processing, thereby enhancing production quality and sustainability.

Researchers from Fraunhofer have developed the new UltraPLAS coating, a solution to solve challenges of primary forming processes.

As a matter of fact, this advanced release and easy-to-clean coating

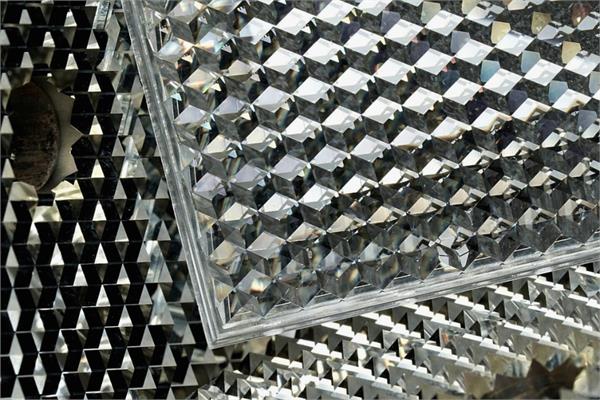

is applied as a gradient layer using a cold plasma process and is suitable for materials such as tool steel, stainless steel and aluminium. The unique physical properties of UltraPLAS also enable perfect moulding of nano-scaled and reflective surfaces. In addition, by reducing the number of post-processing steps and renouncing external release agents, the application is classified as highly economical.

The researchers investigated how sophisticated, high-quality tool surfaces could be coated in order to improve production and significantly delay or simplify cleaning processes together with the partners of the 'GlossyCast' and 'UltraTrenn' projects, which were financed by the Industrielle Gemeinschaftsforschung IGF. The aim of the research projects was to reduce demoulding forces and deposit formation by permanently resisting the specific stresses of high-pressure zinc die-casting and plastic injection moulding.

In particular, the injection moulding of technical plastic parts requires solutions to reduce demoulding forces and the formation of deposits. This applies to the production of components with glossy surfaces or highly defined microstructures, such as plastic lenses, decorative finishes or connectors with high dimensional accuracy. On the other hand, in high-pressure zinc die-casting, deposits on the mould surface and deposits of mould release agents and lubricants prevent the production of glossy, high-quality zinc castings, increasing the post-processing costs of castings. Thus, the application of release agent alone can account for up to 20% of the cycle time, saving considerably if release agents are no longer required.

UltraPLAS enables good coating properties

The coating itself must be smooth and structureless to meet the aforementioned requirement-profile of ultra-smooth, optical surfaces (Ra < 25 nm) within the projects by using the cold plasma process (PE-CVD process, plasma enhanced chemical vapor deposition). This process thus enables excellent layer adhesion to the product body and exceptional non-stick properties with excellent physical characteristics on the product side by building up a gradient layer.

For example, the coating produced in this way is characterised by a high modulus of elasticity (28 - 32 GPa) and a high density (1.5 g/cm³). This results in a Mohs hardness range of 5.5, which is on par with glass or enamel. Moreover, as a non-stick coating, it has a low surface energy (< 28 mN/m) with low polarity (< 1.5 mN/m).

To further support this, Fraunhofer researchers have succeeded in producing the UltraPLAS coating with a particularly thin layer thickness of less than 100 nm, proving to be necessary in the GlossyCast project to provide a good non-stick effect. In addition, the thin, structureless layers allow both nanoscale surface structures, for nanoimprint process and mirror-gloss surfaces to be perfectly reproduced.

Sustainable quality and economical production

Extensive practical tests across various industrial sectors have revealed notable improvements in injection moulding processes. These studies show that demoulding forces and deposit formation are reduced, thanks to decreased adhesion forces. This reduction in adhesion allows for higher demoulding temperatures and reduced friction.

Plasma technology offers a significant advantage over traditional methods by enabling the effective and gentle removal of coatings. This is especially beneficial for high-gloss tool surfaces, as it eliminates the need for time-consuming polishing or precision machining. The technology also permits the reapplication of new coatings multiple times without compromising quality.

Advancements in zinc die-casting technology have led to substantial gains in economic efficiency. By achieving high-quality surfaces directly through casting, costly and labour-intensive post-processing steps, such as blasting, grinding, and polishing, are minimised or avoided altogether. This also shortens or reduces the steps involved in electroplating, resulting in significant cost savings.

The UltraPLAS release coating represents a major advancement in foundry technology. By removing the need for release agents, pretreatment time for electroplating is reduced, and material consumption is lowered. Improved surface smoothness means that bright copper plating is often unnecessary, leading to additional savings in materials, time, and wastewater. Reducing the thickness of copper (cyanide) and bright nickel layers by 50% each further contributes to these savings.

Background information on the development process

This development builds upon the foundation established by the PLASLON non-stick coating, known for its high hardness (Mohs hardness 4.5 - 5.5) and excellent temperature resistance up to 230°C. Initially designed for cookware, PLASLON’s PFAS-free, easy-to-clean properties have facilitated innovations like UltraPLAS. Ongoing product developments, including UltraPLAS and PLASLON, contribute significantly to enhancing production processes

and promoting sustainability within the industry.